Aperam MA5 | Nitrox (Nitrox) is a martensitic stainless steel with a high degree of hardness and improved corrosion resistance for knife blades and cutting tools. Unlike existing steel offerings on the market containing alloying elements such as molybdenum, tungsten, and vanadium, Aperam has developed a grade with similar properties by adjusting the addition of elements less sensitive to price fluctuations (nitrogen, chromium).

Nitrox steel (from the author: Nitro x, Nitro-x) is perfectly suited for blades, knives intended for cutting food products that require high corrosion resistance. Nitrox has a fairly high hardening capacity. The steel is also used for the production of mechanical parts, industrial blades, cutting tools, and more.

In classic martensitic stainless steels, high hardness, which ensures a good cutting edge, is achieved thanks to a high carbon content.

However, increasing the carbon content complicates and renders incomplete the dissolution of chromium carbides during heat treatment. The presence of coarse primary carbides and the depletion of the martensitic matrix in chromium negatively affect corrosion resistance and the quality of the surface after polishing.

Usually, for steel grades with high carbon content, corrosion resistance is improved by adding molybdenum, but this element is very expensive compared to chromium.

Optimal hardness and corrosion resistance for the MA5 steel grade are achieved by adding a significant amount of another element - nitrogen. Nitrogen has a double advantage: it hardens, just like carbon (which it can partially replace), and simultaneously improves corrosion resistance. In addition to nitrogen, increased chromium content ensures very good corrosion resistance without the addition of molybdenum.

This grade complies with the following regulatory documents:

- The Stainless Europe Material Safety Data Sheet (MSDS): stainless steels (European Directive 2001/58/EC).

- European Directive 2013/28/UE on end-of-life vehicles and its annex II dated 27 June 2002.

- Standard NFA 36 711 « Stainless steel intended for use in contact with foodstuffs, products and beverages for human and animal consumption » (non-packaging steel).

- Standard NSF/ANSI 51 for « Food Equipment Materials » and of the F.D.A. (United States Food and Drug Administration) regarding materials used in contact with food.

- French Decree No.92-631 dated 8 July 1992 and Regulation No. 1935/2004 of the European Parliament and of the Council dated 27 October 2004 on materials and articles intended to come into contact with food.

- French Ministerial Order dated 13 January 1976 relating to materials and articles made of stainless steel in contact with foodstuffs.

- The EDQM (European Directorate for the Quality of Medicines & HealthCare) recommendation; the publication « Metals and alloys used in food contacting materials and articles - A practical guide for manufacturers and regulators - 1st edition 2013 ».

Chemical composition of Aperam MA5 | Nitrox steel grade | ||||||

| C | Mn | Cr | Mo | SI | N | Fe |

| 0,35 | 0,35 | 16,0 | - | 0,35 | 0,15 | Other |

Main Features

The main features of MA5 steel are:

- Its capacity for hardening to a high level at a moderate austenitising temperature (standard heat treatment).

- Its capacity for additional hardening by cold treatment after quenching (improved heat treatment).

- Its good shock resistance after low temperature tempering.

- Its very good corrosion resistance.

Applications The MA5 grade is recommended for the following applications:

- Blades for knives and various utensils for food preparation (mid-range and top of the range segments).

- Blades for industrial equipment.

- Cutting tools.

- Mechanical parts and other tools segments.

Physical properties

- Density (4 °C) - 7.7;

- Melting temperature (°C) - 1400;

- Specific heat capacity (c J/kg·K) at 20 °C - 460;

- Thermal conductivity (W/m·K)

- at 20 °C - 30;

- at 200 °C - 31;

- Average expansion coefficient (10⁻⁶ /K)

- at 20-200 °C - 11;

- at 20-400 °C - 12;

- Electrical resistivity (Ω·m) at 20 °C - 6.2⋅10-7;

- Relative permeability (H=800 A/m) at 20 °C - 700;

- Young’s modulus (GPa) at 20 °C - 215;

Mechanical properties

After annealing (as-delivered state)

In accordance with ISO 6892-1, Part 1

Specimen perpendicular to the rolling direction.

Lo: 80 mm (thickness < 3 mm), 5.65 √ So (thickness ≥ 3 mm).

| Tensile Strength | (1) (MPa) | Rp0,2 (2) (MPa) | A (3) % | Hardness HRB |

| Typical values | 680 | 390 | 21 | 89 |

▸ (1) Tensile strength (Rm) ▸ (2) Yield Strength (Rp 0,2 ) ▸ (3) Elongation (A)▸

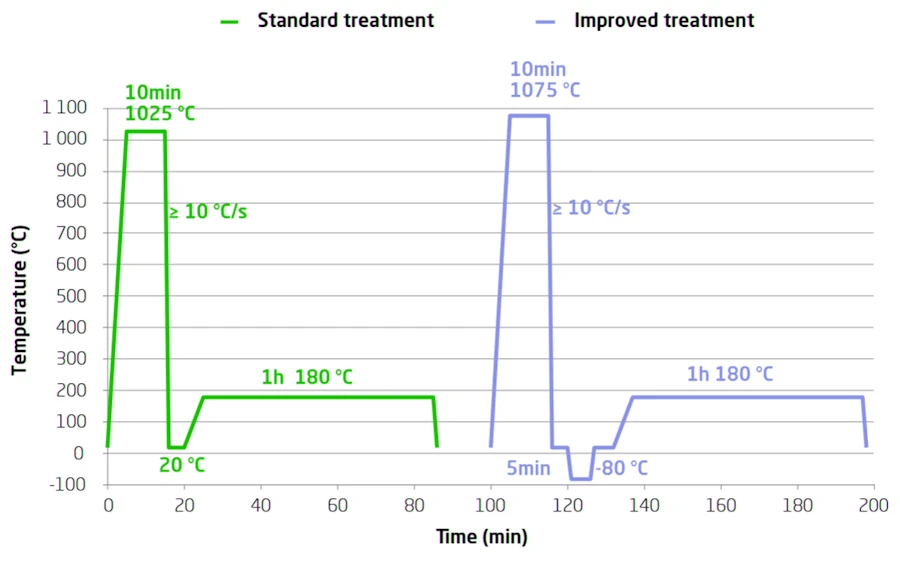

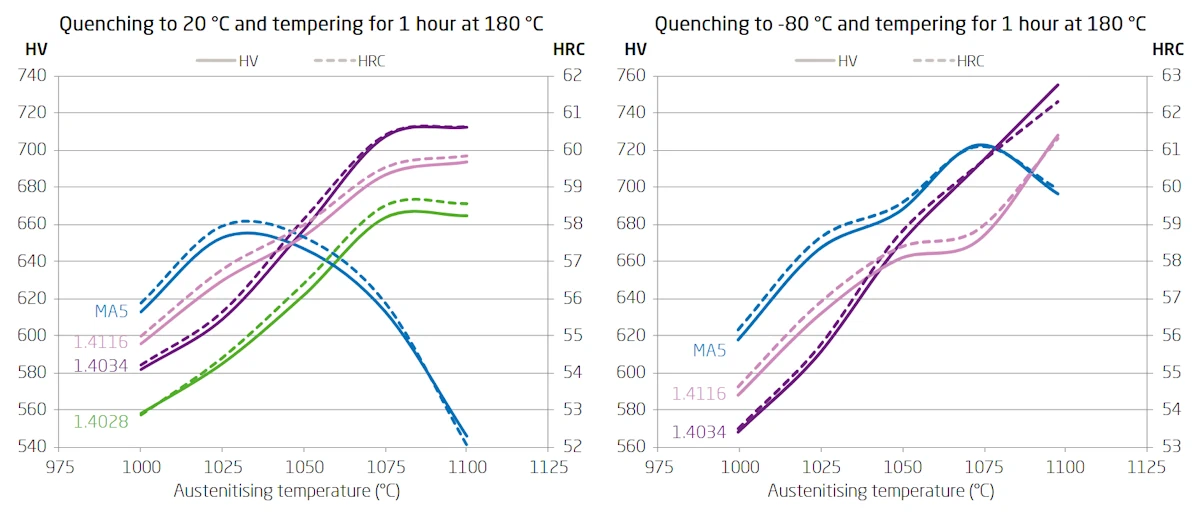

| Hardness Typical values (1) | 10 minutes at 1025°C. Forced air cooling to 20°C. Tempering for 1 hour at 180°C. | 10 minutes at 1075°C. Forced air cooling to -80°C. Tempering for 1 hour at 180°C. | ||

| Grades | HRC | HV | HRC | HV |

| 1.4028/MA3 | 54.4 | 585 | - | - |

| 1.4034/MA4 | 55.7 | 609 | 60.6 | 711 |

| 1.4116 | 56.8 | 630 | 58.8 | 671 |

| MA5 | 58.0 | 653 | 61.1 | 722 |

1) Values are not guaranteed as obtained after heat treatment in the laboratory by taking into consideration the temperature of the metal and not that of the furnace.

Influence of the austenitising temperature on MA5 steel hardness.

The MA5 grade reaches its maximum hardness for austenitisation at 1025 °C after quenching at 20 °C and tempering at 180 °C. In these processing conditions, called standard because they are easily accessible on industrial equipment, the MA5 grade has higher levels of hardness than the 1.4034 and 1.4116 grades (figure on left).

At austenitisation temperatures higher than 1025 °C the hardness of the MA5 grade goes down. This is due to an excessive level of retained austenite resulting from the high chromium content of this grade, which lowers the Mf temperature to below room temperature.

For additional hardening, the dissolution of chromium carbides must be continued by increasing the austenitisation temperature, but also cold treatment below the Mf temperature must be performed, so that the transformation of austenite to martensite is complete. Thanks to cryogenic treatment at -80 °C after quenching, the maximum hardness is obtained by performing austenitisation at 1075 °C. This improved treatment allows for increasing the level of hardness by about 3 HRC compared to the standard treatment, which allows the MA5 grade to retain a level of hardness that is higher than the 1.4034 and 1.4116 grades after the same treatment (figure on right).

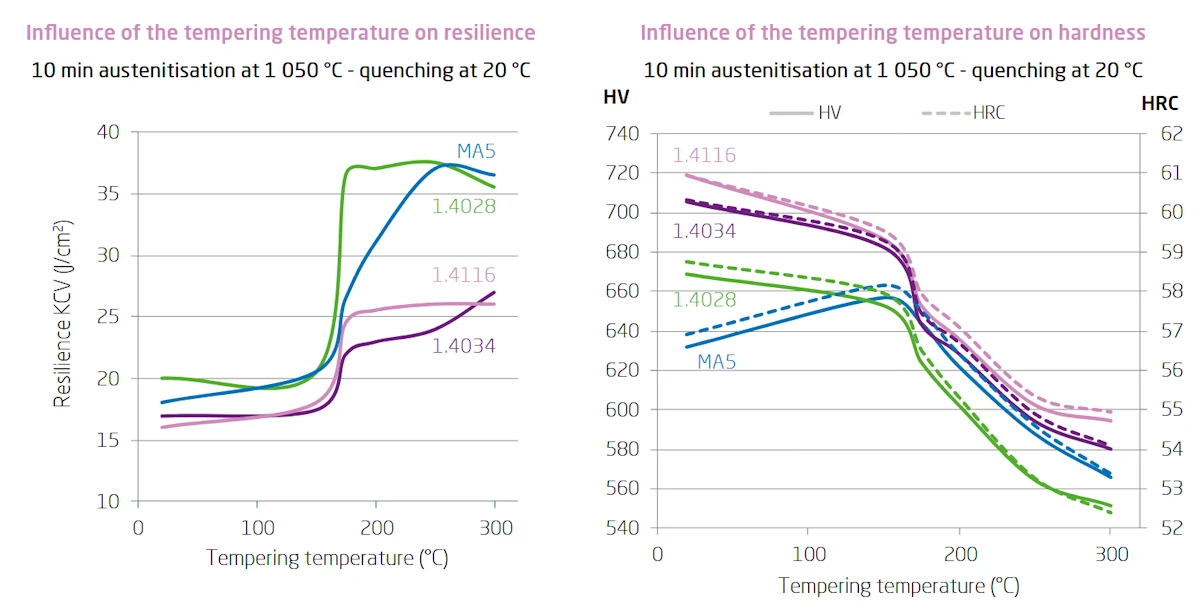

Tempering aims to reduce the fragility of the raw material of quenching by relaxing residual stresses and allowing a very limited re-precipitation of fine chromium carbides and nitrides. The improvement in fragility is monitored by measuring impact resistance using the Charpy impact test. The improvement is only significant starting from a tempering temperature of 180 °C.

The less carbon the grade contains the more significant it is, since the MA5 grade has superior impact toughness than the 1.4034 and 1.4116 grades (figure on left).

Hardness decreases with increasing tempering temperatures for the carbon grades, while for the nitrogen MA5 grade it increases before decreasing - which brings it after tempering at 180 °C to the same level of hardness as in the raw quenched state (figure on right).

Tempering at 180 °C is, therefore, the optimum for MA5 because it improves shock resistance sufficiently without degrading the level of hardness relative to the raw quenched state.

Corrosion resistance

Influence of heat treatment conditions

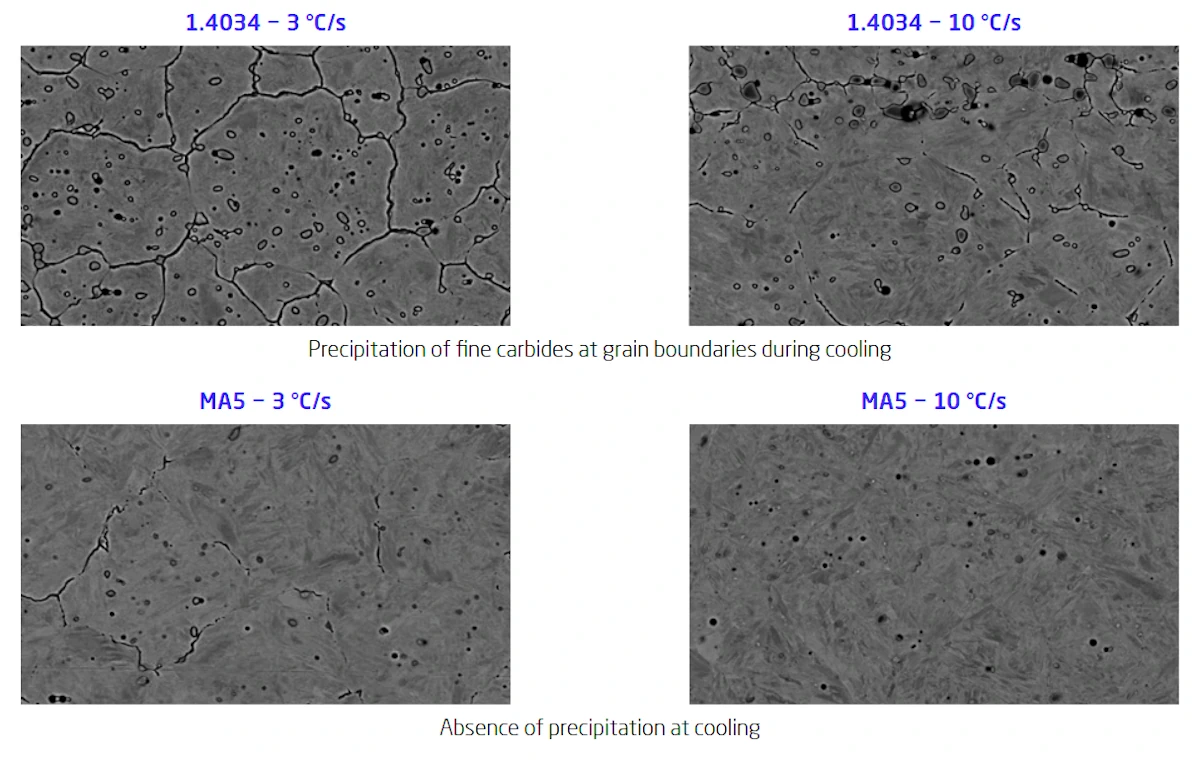

Corrosion resistance depends on the hardening and tempering conditions used and mainly on the cooling rate after austenitisation. Below the critical cooling rate, of the order of 10°C/s, a loss of resistance to pitting corrosion is observed, due to the precipitation of chromium carbides and nitrides leading to a depletion in chromium around the precipitates. In practice, this means that simple air cooling is to be banned and that cooling must be done using forced reductive gas or oil quenching.

Heat treatment: austenitisation for 10 minutes at 1050°C followed by cooling at different cooling rates to 300°C. SEM (Scanning Electron Microscope) observations of the mirror polished state after light electrochemical etching.

MA5 is less sensitive to the cooling rate than grades with a higher carbon content like grade 1.4034 (see figure above). However, a cooling rate of at least 10°C/s is recommended to avoid all risk of precipitation during cooling.

Tempering conditions can also degrade corrosion resistance. Indeed, a tempering temperature higher than 300°C should also be banned because it leads to the precipitation of chromium carbides and nitrides and, therefore, to localised chrome depletion.

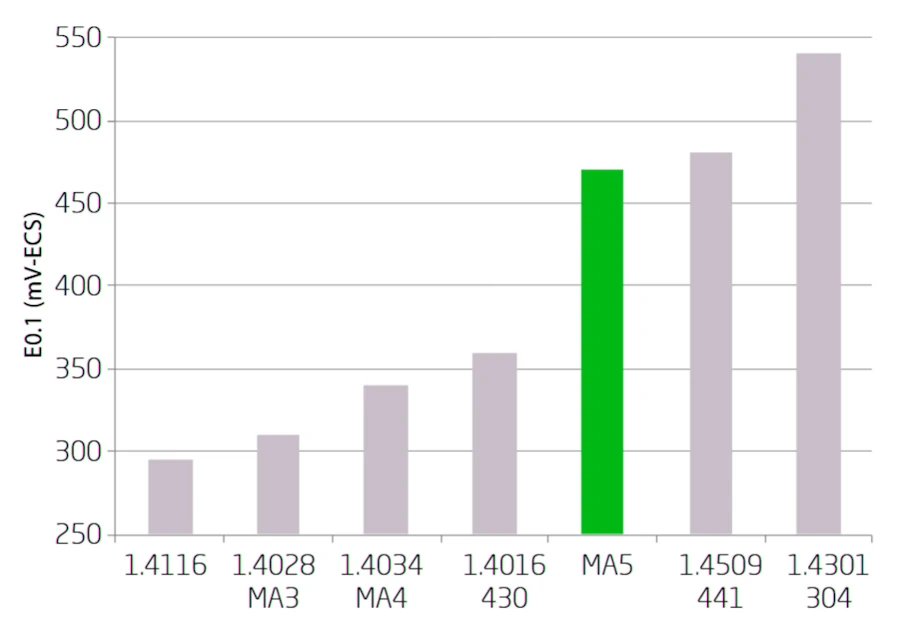

Resistance to pitting corrosion

Corrosion resistance depends on the chemical composition of the steel. The favourable chemical elements are chromium, molybdenum and nitrogen and, specifically for martensitic stainless steels, the unfavourable chemical element is carbon due to its ability to consume chromium in the form of chromium carbides not completely dissolved during austenitisation. Susceptibility to pitting corrosion is measured using an electrochemical multi-pitting test which gives access to its pitting potential. The higher the pitting potential, the more the grade is resistant to pitting corrosion.

The chemical composition of MA5 has been specially adjusted (high-Cr, high N, moderate C) to guarantee good resistance to pitting corrosion, significantly higher than carbon-based grades of martensitic stainless steels. MA5 has the same resistance to pitting corrosion as the stabilized ferritic 1.4509 grade (18% Cr, TiNb), and is situated between that of the ferritic 1.4016 (16% Cr) and that of the austenitic 1.4311 (18% Cr−8% N). MA5 knives are, therefore, just as suitable as any other cutlery to be washed in the dishwasher.

Multi-pitting test in 0.02M NaCl, 23°C, pH=6.6.

Effect of mechanical operations

Localised heating due to mechanical finishing operations such as grinding, sharpening, polishing, or grooving must not induce temperatures higher than that recommended for tempering.

Finally, surface condition is another factor that can affect corrosion resistance. Where it concerns polishing, a low surface roughness is always preferable.

Alimentarity / food contact suitability

MA5 is suitable for contact with food. It meets criteria for release tests (migration) in accordance with the recommendations of the EDQM (European Directorate for the Quality of Medicines & HealthCare) and the Italian Decree dated 21 March, 1973.

Its release rate for a mirror polished surface state (1 μm diamond-impregnated felt finish) as for a 1200 grade polished surface state (1200 grit silicon carbide sandpaper) is well below the required thresholds.

Welding

As with all martensitic stainless steels, certain precautions are necessary when welding MA5, since the Martensitic transformation tends to cause cracking (sometimes of a delayed nature) at temperatures below 400°C. It is recommended to preheat parts to about 200°C before welding them.

In welding processes requiring the use of shielding gas (TIG, MIG, plasma), the use of hydrogen and nitrogen is strictly forbidden.

Martensitic stainless steels can be assembled by spot welding and seam welding, and also by arc welding.

A post-weld heat treatment is recommended.

When welding is performed without filler metal, the following postweld heat treatments can be used:

- Softening (Annealing) between 650 and 800°C, but in this case corrosion resistance is degraded.

- Austenitisation at 1025°C, followed by tempering at 180°C.

When welding is carried out with a filler metal, the choice is between:

- An alloy having the same composition as the base metal (homogeneous welding with AWS 420 electrode or wire), with postoperative heat treatment as above if it is desired to obtain the same hardness of the weld and base metal.

- An alloy of different composition from the base metal (heterogeneous welding with electrode or austenite wire of type ER 308L, 309L or 316L in accordance with EN-ISO 14343), but a postoperative heat treatment will always have to be applied to prevent embrittlement of the H.A.Z. (Heat Affected Zone).

| Welding process | Without filler material | With filler metal | Shielding gas | ||

| Typical thicknesses | Thicknesses | Filler metal | Hydrogen and nitrogen forbidden in all cases | ||

| Rod | Wire | ||||

| Resistance welding: spot, seam | ≤ 2 mm | - | - | - | - |

| TIG | ≤ 1.5 mm | > 0.5 mm | ER 309 L (Si) ER 420 (1) | ER 309 L (Si) ER 420 (1) | Ar, Ar + He |

| PLASMA | ≤ 1.5 mm | > 0.5 mm | - | ER 309 L (Si) ER 420 (1) | Ar |

| MIG | - | > 0.8 mm | - | ER 309 L (Si) ER 420 (1) | Ar + 2 % CO2 or Ar + 2 % O2 |

| S.A.W. | - | > 2 mm | - | ER 309 L (Si) ER 420 (1) | - |

| Electrode | - | Repairs | ER 309 L (Si) ER 420 (1) | - | - |

| Laser | ≤ 5 mm | - | - | - | He |

1) The homogeneous filler metal ER 420 should be used when subsequent quenching and tempering is to be performed in order to obtain the same hardness in the weld and the base metal.

Pickling

The welds must be pickled and repassivated to obtain the corrosion resistance of the base metal.

Pickling can be done in a bath or locally using specific pastes designed for stainless steels.

For pickling a mixture of nitric acid and hydrofluoric acid may be used (15% HNO3 + 1% HF). For passivation nitric acid at 25% can be used (2 hours at 20°C or 10 min at 50°C) followed by thorough rinsing with cold water (according to EN−ISO 14343).