PMD550 is a high-tech powder stainless steel from the German concern DOERRENBERG, designed for the production of high-performance knives and tooling due to its excellent cutting ability and wear resistance. The steel contains a high percentage of carbon (2.6%), chromium (17%), vanadium (3.3%), and cobalt (2%), ensuring high hardness (over 63 HRC), abrasive wear resistance, and good impact toughness.

PMD 550 is an advanced material that has been specially developed for applications with extreme requirements for wear resistance and corrosion resistance. The martensitic stainless steel, manufactured by powder metallurgy, combines the latest material technologies with practical application flexibility.

PMD-550 is a true all-rounder. Typical applications can be found in the plastics industry, especially in the processing of fiberglass and highly abrasive plastics. In the food industry, where the highest standards of hygiene and corrosion are required, it also offers significant advantages due to its resistance and hardness. In addition, the material is ideally suited for highly stressed wear parts in mechanical engineering and molding technology.

PMD 550 impresses with its fine, homogeneous microstructure, achieved through the powder metallurgy production process. Evenly distributed, fine carbides provide exceptional wear resistance while simultaneously increasing the material's thermal stability. Compared to conventional steels or the proven PMD440, PMD550 offers an extended range of performance characteristics, especially under high mechanical and thermal loads.

The steel is usually supplied in the soft annealed condition up to max. 330 HB.

Chemical Composition

The chemical composition with cobalt increases the hardness of the martensitic matrix as a solid solution strengthener, providing excellent support for wear-resistant carbides. Cobalt also increases the start temperature of martensite formation. Thus, after hardening, PMD550 is less prone to retained austenite compared to the cobalt-free steel variant. The chemical composition with a high chromium content of about 17% ensures excellent corrosion resistance, while the increased carbon and vanadium content promotes the formation of hard carbides.

| Chemical composition of PMD550 steel grade | |||||

| C | Cr | Mo | V | Co | Fe |

| 2,66 | 17,0 | 1,8 | 3,3 | 2,0 | Other |

Hardening and coating - for maximum performance

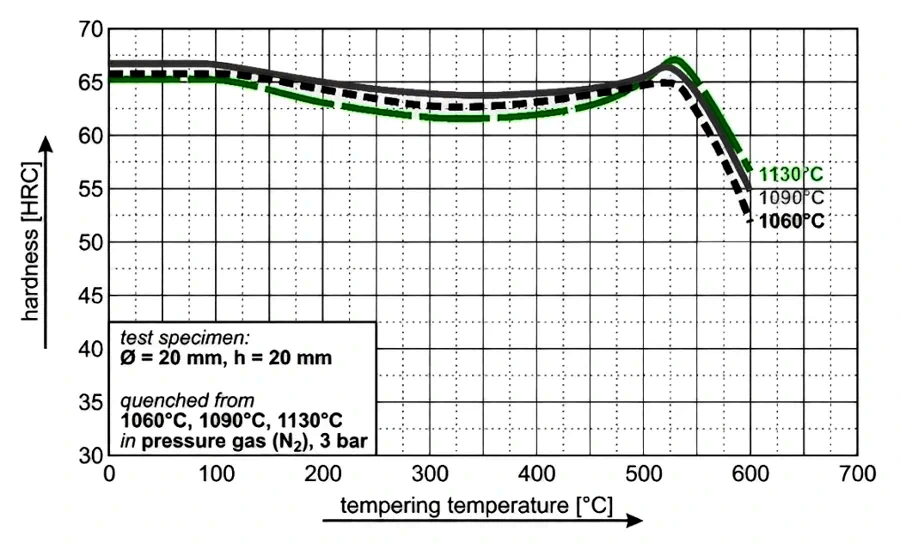

One of the key advantages of PMD550 is its excellent heat treatability. Thanks to targeted austenitization followed by appropriate hardening, a very strong martensitic structure can be created. Subsequent tempering allows the final hardness and toughness to be precisely adjusted, achieving hardness values exceeding 63 HRC. Despite the high hardness, corrosion resistance remains at a very good level - a crucial advantage compared to traditional tool steels.

Furthermore, the combination of PMD550 with modern PVD coatings offers additional performance benefits. These can be applied to the hardened material, which further increases wear resistance and tribological properties, especially in highly abrasive application conditions. Thanks to the high hot strength of the base material, the characteristics and service life of the coating are maintained even at elevated process temperatures. This makes PMD550 ideal for hybrid solutions that must meet both maximum surface hardness and corrosion protection requirements.

Steel properties

Powder metallurgy martensitic stainless steel with high Co content, high carbide volume with finely distributed carbides, and a homogeneous microstructure across the entire cross-section.

Compared to PMD440, higher hardness and higher hardness stability at elevated temperatures.

Applications

Steel PMD550 is positioned as a true all-rounder thanks to its exceptional combination of high wear resistance, hardness (over 63 HRC), and corrosion resistance. This makes it an ideal choice for critically stressed and aggressive working environments.

1. Plastics industry and processing of abrasive polymers

This is one of the key applications. PMD550 is excellently suited for tools that come into contact with highly abrasive plastics, especially those containing fiberglass or other fillers. Under these conditions, conventional steels wear out quickly.

- Typical parts: extrusion screws, nozzles, molded inserts, and other highly stressed elements of casting molds.

- Advantage: the ability to simultaneously resist abrasive wear (from fillers) and potential corrosion (from polymer decomposition products).

2. Food industry

In this industry, the highest demands are placed on materials regarding hygiene and corrosion resistance.

- Typical parts: cutting elements, grinders, knives for industrial food processing, pump and valve parts.

- Advantage: high chromium content (17%) provides excellent corrosion resistance to detergents, acids, and salts used in cleaning and processing, and high hardness guarantees a long service life.

3. Production of high-performance knives and tooling

Thanks to its exceptional cutting ability, high hardness, and impact toughness, PMD550 is an ideal material for cutting tools.

- Knives: elite kitchen, hunting, and industrial knives where the ability to hold a cutting edge for a long time, even after intensive use, is required.

- General tooling: dies, punches, cutters, and other highly stressed parts that require a combination of wear resistance and mechanical strength.

4. Mechanical engineering and molding technology

The material is used for the production of highly stressed wear parts.

- Typical parts: guides, bushings, rollers, and other elements subjected to constant friction, high pressure, and elevated temperatures.

- Features: retention of characteristics at elevated temperatures (high hot strength) and a homogeneous microstructure that minimizes the risk of premature failure.

Physical properties

| Coefficient of thermal expansion | 10-6⋅m m ⋅ K | 20-100°C 10,7 | 20-200°C 10,8 | 20-300°C 11,2 | 20-400°C 11,6 |

| Thermal conductivity | W. m ⋅ K | 20°C 19,1 | 350°C 21,5 |

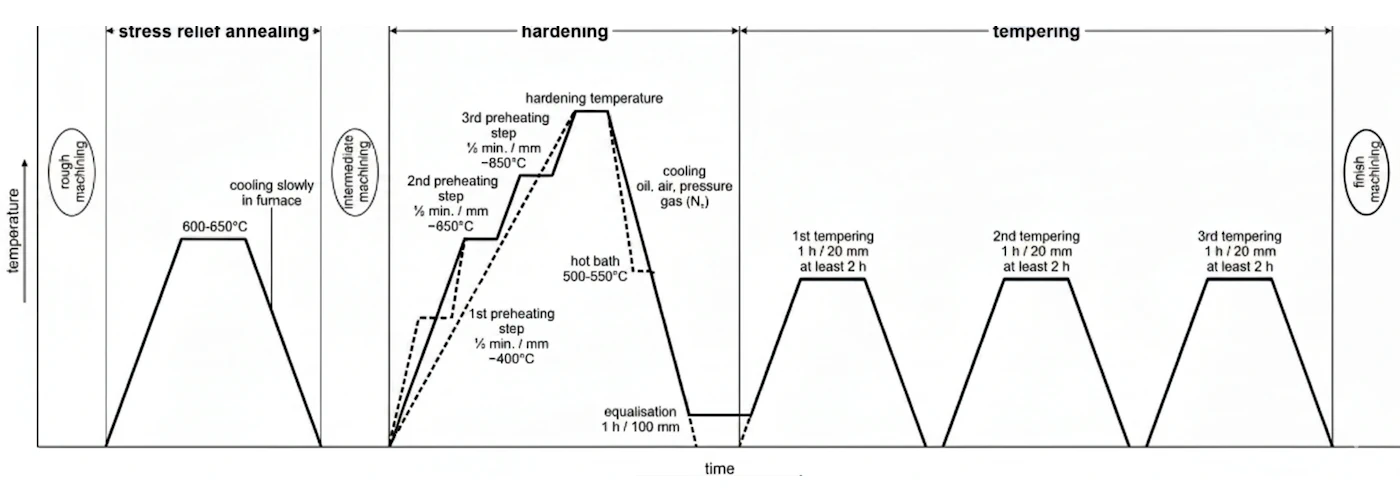

Heat treatment

| Soft annealing (only in neutral atmosphere) | ||

| Temperature | Cooling | Hardness |

| 880 - 900°C | furnace | max. 330 HB |

| Stress relieving | ||

| Temperature | Cooling | |

| 600 - 650°C | furnace | |

| Hardening | ||

| Temperature | Cooling | Tempering |

| 1060 - 1130°C | Oil, pressurized gas (N2), air, or hot bath 500-550°C | See tempering diagram |

PMD550 thermal cycle diagram

PMD550 steel tempering diagram

General conclusion on PMD550 steel

PMD550 is a premium powdered martensitic stainless steel that represents the pinnacle of tool material manufacturing technology from the DOERRENBERG concern.

Thanks to its unique chemical composition (high content of C, Cr, V and the addition of Co) and the powder metallurgy production process, this steel offers an extended range of performance characteristics unavailable to conventional tool steels.

The key value of PMD550 lies in its synergy of properties: it is not just hard or simply corrosion-resistant, but combines exceptional abrasive wear resistance (due to hard vanadium carbides and high carbon) with high corrosion resistance (due to 17% chromium), while maintaining excellent heat treatability and minimal susceptibility to retained austenite (due to cobalt).

PMD550 is a high-tech solution for applications where service life, reliability, and productivity are critical, especially in environments that require simultaneous protection against wear, corrosion, and high mechanical / thermal loads.