RWL-34 is a high-carbon stainless steel powder, additionally alloyed with molybdenum and vanadium. It has medium corrosion resistance. It is produced by the Swedish company Damasteel AB. Hardness 59 - 62 (according to some sources 64) HRC. Very pure metal. The steel got its name from the initials of Robert Waldorf Lovleless, who popularized this alloy for knives.

The closest analogue of the brand is the American powder steel Crucible CPM 154, produced by the Crucible Industries concern. Also similar are the brands 154CM (USA) and ATS-34 (Japan).

RWL-34 (rwl34) is one of the most affordable modern powder stainless steels with a good reputation. It has a good combination of cutting edge durability, corrosion resistance and mechanical characteristics, holds a thin cutting edge well. With high hardness, the steel is well processed - ground and polished, is excellent for blades of complex geometry, one of the best steels for artistic etching.

Properties

Martensitic stainless steel RWL 34 is a rapid solidification powder (RSP) grade of 420 martensitic stainless steel with a chromium content of >13%. The addition of molybdenum and vanadium gives RWL 34 even greater corrosion resistance, hardness and strength. This alloy can be considered for a wide range of applications where one or more of the following properties are important:

- High edge strength

- High hardness after quenching and tempering

- Good corrosion resistance

- Easy to grind and polish

- High alloy purity

Application

The alloy has an excellent combination of corrosion resistance and hardening. This combination of properties is the reason for its remarkable suitability as a material for making knives. Some examples of other applications are cutlery and any other application where corrosion resistance and hardness are important.

Chemical composition

Chemical warehouse steel grade RWL-34 | ||||||

| C | Cr | Mo | Mn | Si | V | Fe |

| 1,05 | 14,0 | 4,0 | 0,5 | 0,5 | 0,2 | Other |

Mechanical and physical properties

Mechanical and physical properties of annealed RWL 34 (plate and sheet), minimum values at 20 °C.

| Yield strength, Rp 0.2 | 270 MPa | Young's modulus | 200 GPa |

| Tensile strength, Rm | <700 MPa | Poisson's ratio | 0,3 |

| Extension, A5 | 45% | Thermal conductivity | 15 W/m K |

| Hardness | <700 HV | Heat capacity | 460 J/kg K |

| Density | 7.8 kg/dm3 | Specific electrical resistance | 0,73 μOhm*m |

Corrosion resistance

Martensitic stainless steels have moderate to good corrosion resistance and are therefore suitable for a wide range of applications. The addition of molybdenum gives RWL 34 higher corrosion resistance than standard martensitic stainless steels.

Hot processing

Hot treatment temperature 1050 - 1160 °C.

Compared to low-alloy steels, martensitic stainless steel has a higher, almost twice as high, resistance to deformation. Therefore, hand forging can only be performed on relatively small dimensions. Melting begins at 1220 °C, which means that the material is very sensitive to overheating. Good control of the heating temperature is necessary. An electric or gas furnace is recommended. Long holding times above 850 °C lead to a significant decrease in the carbon content of the steel and the formation of scale.

After the hot working process, slow cooling is recommended due to the risk of cracking during the transition of the material phase to martensite at a temperature of about 200 °C. The use of vermiculite or other thermal insulation material is recommended.

Heat treatment

Due to the risk of cracking after hot working, grinding, cutting or machining should not be carried out until the material has been annealed. It is recommended to fully anneal the material, which means one hour at 900 °C, then cool to 750 °C for one hour and finally hold at 750 °C for four hours. All Damasteel martensitic materials are soft annealed to 230 - 280 HV (20 - 28 HRC).

Hardening

For use in knife production, the following heat treatment is recommended for a 3.2 mm thick part:

| № | Hardening temperature (A) | Tempering temperature (T) | Tempering time, hours. | Hardness, HRC |

| 1 | 1050 °C | 220 °C | 2 | 59 |

| 2 | 1050 °C | 175 °C | 2 | 62 |

| 3 | 1080 °C | 220 °C | 2 | 58 |

| 4 | 1050 °C | 175 °C | 2 | 63 |

| 5 | 1100 °C | 175 °C | 2 | 64 |

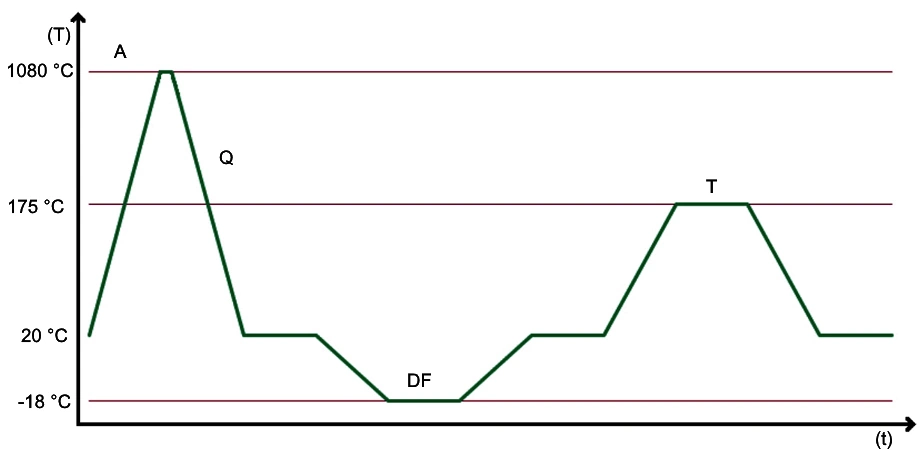

Suggested heat treatment processes No. 4 and No. 5 include deep freezing (DF) at -80 °C. To ensure the best corrosion properties, a low tempering temperature is recommended. The following time-temperature curve can be used as a guide for hardening operations:

- A - austenitization. Holding time is 8 minutes for a part 3.2 mm thick. Increase or decrease the holding time by one minute per half a millimeter of thickness.

- Q - rapid cooling to room temperature. Oil quenching is recommended, and the part should reach room temperature within two minutes. When air cooling, apply some pressure to the part so that it does not bend due to uneven cooling.

- DF - deep freezing is not necessary, but completes the martensitic transformation and increases hardness. Keep for about an hour and a half.

- T - tempering. Holding time is two hours.

Cold processing

Martensitic stainless steels do not cold work as easily as regular austenitic stainless steels, but they can be formed and manufactured using a full range of cold working operations. Cold working ductility is good, and any cold working process will increase the strength and hardness of the material.

Welding

When cooling martensitic stainless steel after any hot process, the martensitic phase transformation occurs at approximately 200 °C and can lead to cracking. This can be avoided by preheating the component or by heat treatment after welding. RWL 34 steel can be welded by the full range of conventional welding methods.

Mechanical processing

As with conventional austenitic stainless steels, martensitic steels have some specific machinability properties. Martensitic stainless steels are generally more difficult to machine than other grades of stainless steel. The machinability characteristics of RWL 34 martensitic stainless steel are:

- Low tensile strength but strong machining strength;

- Tendency for material to accumulate on the tool edge;

- Formation of tough and stringy chips can be prevented by using chip curling tools.

Grinding and polishing

The usual grinding and polishing procedures for austenitic stainless steel can also be used for martensitic stainless steel.

Recommendations for choosing a grinding disc:

Silicon carbide, 46 grit, soft, open density, ceramic bonded. (C46J6V)

- Speed: 35 m/sec

- Feed rate: 0.01 - 0.05 mm/stroke

The workpiece speed can be 1/60 of the grinding speed.

Hardening process:

- Sand the part to the desired shape with a grain size of 60 and 120;

- Harden according to the instructions (see above on the page);

- Fine grinding and polishing with a thin rope and wax;

- Sand the end edge if you are making a knife.

RWL-34: Advantages and Disadvantages

RWL-34 is a high-quality martensitic stainless steel widely used in the knife industry due to its outstanding properties. Let's take a closer look at its advantages and disadvantages.

Advantages of RWL-34:

- High hardness: due to its strong structure, RWL-34 can be hardened to very high hardness, which provides excellent ability to retain the blade's sharpness.

- Good corrosion resistance: RWL-34 steel has sufficient corrosion resistance, which allows it to be used in various conditions, including contact with water and some aggressive environments.

- Good wear resistance: due to its strength, RWL-34 resists wear well, which ensures a long service life of tools made of this steel.

- Good toughness: despite its high hardness, RWL-34 retains sufficient toughness, which reduces the risk of brittle fracture of the blade.

- Ease of sharpening: RWL-34 steel is relatively easy to sharpen, which allows you to maintain the blade's sharpness without much effort.

Disadvantages of RWL-34:

- High cost (price): due to its properties and complexity of production, RWL-34 steel is quite expensive.

- Sensitivity to overheating: during heat treatment, RWL-34 can lose its properties when overheated, so it requires experience and precision when hardening.

- Difficulty in processing: RWL-34 steel is relatively difficult to process, which requires the use of special equipment and tools.

Conclusion:

RWL-34 is a great choice for those looking for a strong, durable and sharp knife. However, the high cost and complexity of processing may be limiting factors for some users. Before choosing a knife made of this steel, you should consider all its advantages and disadvantages.