ZDP-189 is a powder high-chromium, ultra-high-carbon tool stainless steel of the highest category, produced by Hitachi Metals Corporation (Japan). Developed on the basis of the technology of amorphous metal alloys used for the manufacture of knives. Allows to obtain very high hardness (up to HRc 69 - 70 HRc).

Due to the three percent carbon content in the alloy, it should be considered cast iron, but it is classified as high-carbon stainless steel by classifiers due to the modern powder technologies that were used in its production.

After ZDP-189 went on sale, knife makers' opinions on the properties of this new steel for making knives were divided into two groups: - some admired the high cutting properties, others, on the contrary, said that the steel was very brittle and the cutting edge was constantly worn out. Such a difference in thoughts is quite clear. ZDP-189 steel is not recommended for use on blades with concave descents, and it was not originally intended for such purposes. ZDP-189 was created for professionals who value high cutting qualities of a knife and understand what blade geometry is intended for what tasks.

Steel grade ZDP-189 - was made in Japan. Developed in 1996 at Hitachi Metals. Kitano Katsumi and Koji Hara took part in its creation. 189 is the number of the experiment that resulted in this stainless steel.

The steel has a very high carbon and chromium content. Specially developed hardening technology followed by (according to some sources) cryogenic treatment. Very high hardness: 64-67 HRC, according to some sources with an upper limit of 69 - 70 HRC. Carbide content is about 36%.

The steel has very good edge retention. On the other hand, ZDP-189 is quite brittle and is usually used in facings made of other steels, usually ATS34. Its corrosion resistance is said to be sufficient, although this issue is often ignored. It is not recommended for knives with concave bevels. Compared to other knife steels, it is considered difficult to sharpen. The price, as you might guess, is not small.

In terms of chemical composition, ZDP-189 steel is very similar to Japanese Cowry-X steel. Stainless steel MC66 is also an analogue of ZDP-189 steel.

ZDP-189 (Hitachi Metals Ltd.) is a powder metallurgy super steel developed to compete with Cowry X. It has a similar chemical composition to Cowry X and offers similar performance levels. Unfortunately, due to the complexity of ZDP-189 production and the special forging and heat treatment it requires, knives made from this steel are expensive and relatively rare.

Peculiarities

- Powder steel with a homogeneous and fine microstructure;

- Chemical composition: Fe - 3%C - 20%Cr;

- Excellent wear resistance due to high hardness (from 66 to 68-70 HRC);

- Good chip resistance;

- Good corrosion resistance.

Chemical composition

Chemical composition of steel grade ZDP-189 | |||||||

| C | Cr | Mo | W | V | Mn | Si | Fe |

| 3,0 | 20,0 | 1,4 | 0,6 | 0,1 | 0,5 | 0,4 | Other |

ZDP-189 is the hardest powder metallurgy stainless steel available today. Apart from HAP40, there is currently no other steel used for knives with comparable properties. The 3% carbon content makes the steel extremely hard, while the 20% chromium content counteracts the steel's strong rust formation.

However, sharpening this steel requires experience, as it is not as easy to sharpen compared to HAP40. The initial cost of a ZDP knife is also comparatively high, as the steel is more expensive and also can be forged less quickly than other types of Japanese steel. However, you get an exceptional material that, with the exception of HAP40, is not comparable to any Japanese knife steel.

Heat treatment

Heat treatment conditions

| Recommended condition | Hardness HRC | ||

| Hardening | Austenitization | 1000 - 1050 ℃, air or oil cooling plus sub-zero temperatures | minimum 65 |

| Tempering | 100 to 150 ℃, air cooling | ||

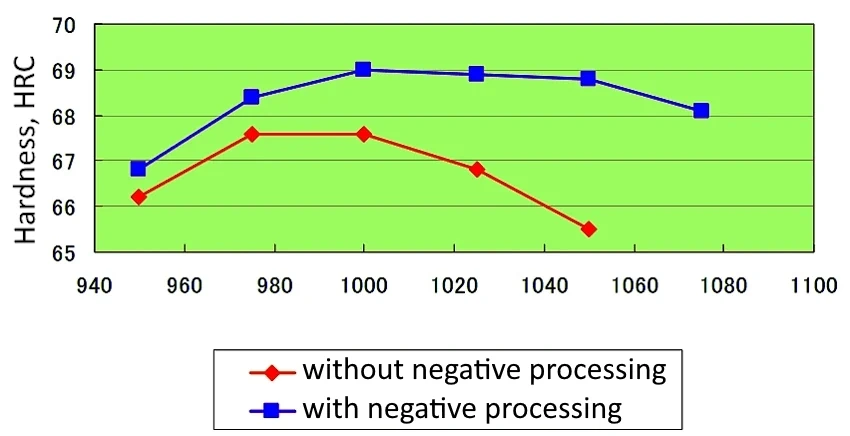

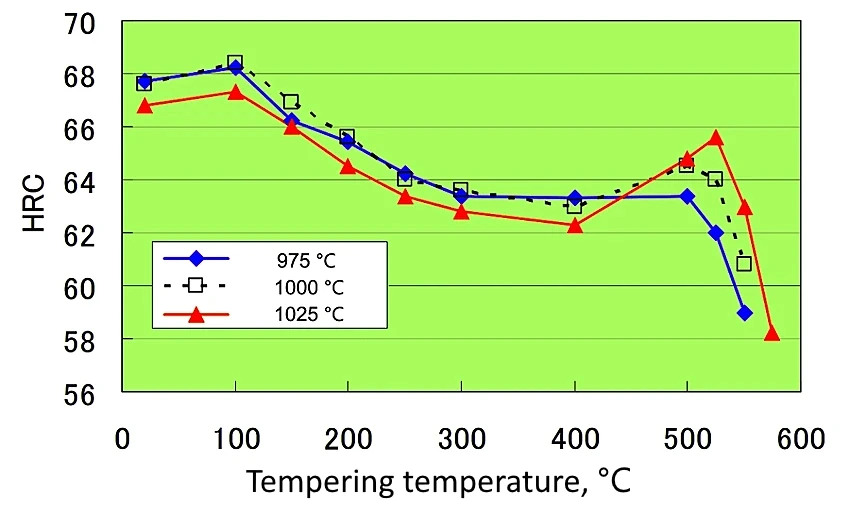

Properties of heat treatment

Notes:

- cooling medium: air

- processing at negative temperatures: ‐75 ℃

Hardness of quenching without treatment at sub-zero temperatures

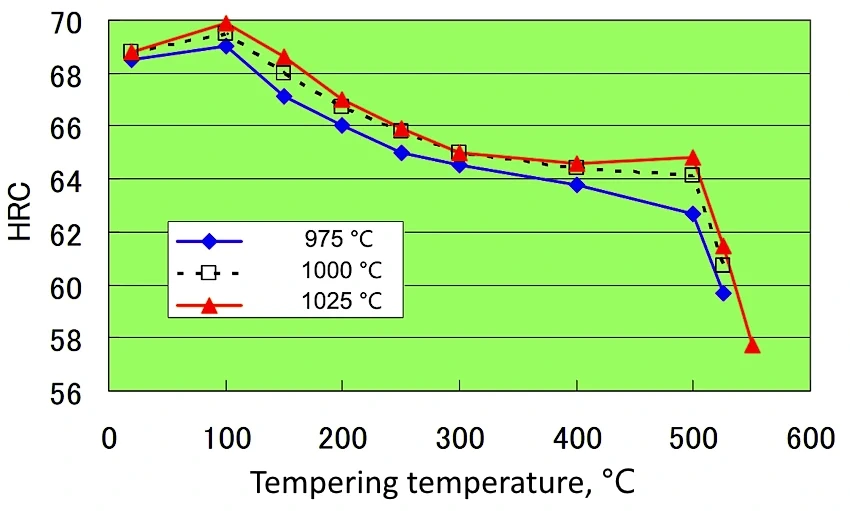

Hardness of quenching at sub-zero temperature processing

Notes:

- cooling medium: air

- processing at sub-zero temperatures: ‐75 ℃

Conclusion

ZDP-189 is a high-quality Japanese stainless steel PM (powder metallurgy), specially developed by Hitachi Metal for custom knives and premium cutlery in cooperation with well-known Japanese custom knife manufacturers. It combines extreme hardness (65-67 HRC), strength, good corrosion resistance and ideal aesthetics. ZDP189 has a uniform and fine microstructure and does not contain coarse carbides, so blades made from ZDP189 can be sharpened to incredible sharpness.

All technical information contained here is representative of this alloy and does not guarantee the quality of the application.