Stainless steel is a versatile alloy widely used in various industries including aerospace, construction, automotive, pharmaceutical, etc. Stainless steel tubes are commonly used in these industries and cutting them to the desired shape and size is an important step in working on a specific project. In this article, we will look at the best methods and techniques for cutting stainless steel tubes and the tools commonly used for this purpose.

Cutting stainless steel pipes is very important to achieve the desired design, shape and size. Stainless steel is very difficult to cut. There are several methods for cutting stainless steel pipes, each with its own advantages and disadvantages. Here are some of the most popular methods:

1. Cutting with a grinder:

- Advantages: this is a quick and easy method that can be used to cut pipes of different diameters.

- Disadvantages: it can cause deformation of the pipe and the formation of burrs that must be removed before further use. It is also important to use safety glasses, a respirator, and gloves to avoid injury.

An angle grinder is a versatile tool that can cut and grind stainless steel pipes. Before cutting, mark the pipe to ensure accuracy. Move the cutting disc of the angle grinder to the desired position and cut the stainless steel pipe. One of the advantages of using an angle grinder is that it does not require cutting fluid. It can also cut hard stainless steel pipes. When cutting, use protective equipment as sparks may occur when the cutting disc comes into contact with the stainless steel.

2. Cutting with hacksaws for metal:

Advantages:

- Simplicity: cutting with hacksaws for metal is a simple and accessible method that does not require special equipment or skills.

- Flexibility: hacksaws can be used to cut pipes of different sizes and shapes.

- Accuracy: when used correctly, a hacksaw can produce precise cuts.

- Portability: hacksaws are compact and lightweight, making them convenient for use in the field.

Flaws:

- Time: cutting metal with hacksaws can be labor intensive and time consuming, especially for thick-walled or large pipes.

- Physical strain: cutting with hacksaws can be physically taxing, especially when cutting thick walled stainless steel pipe or large diameter / section stainless steel pipe.

- Danger: improper use of a hacksaw can result in injury.

- Quality: cutting with hacksaws can result in uneven cuts that may require additional processing.

- Limitations: hacksaws are not suitable for cutting pipes that are too thick or too large.

A hacksaw is another tool that can be used to cut stainless steel pipe. The blade is attached to a frame with thin edges that cut smoothly through the wall of the pipe. Before using the hacksaw, secure the stainless steel pipe with clamps. Move the hacksaw back and forth to cut the pipe. Use deburring tools with the inside edges to smooth them. It is important to place the pipe securely and ensure that the blade is in the correct position for safe cutting.

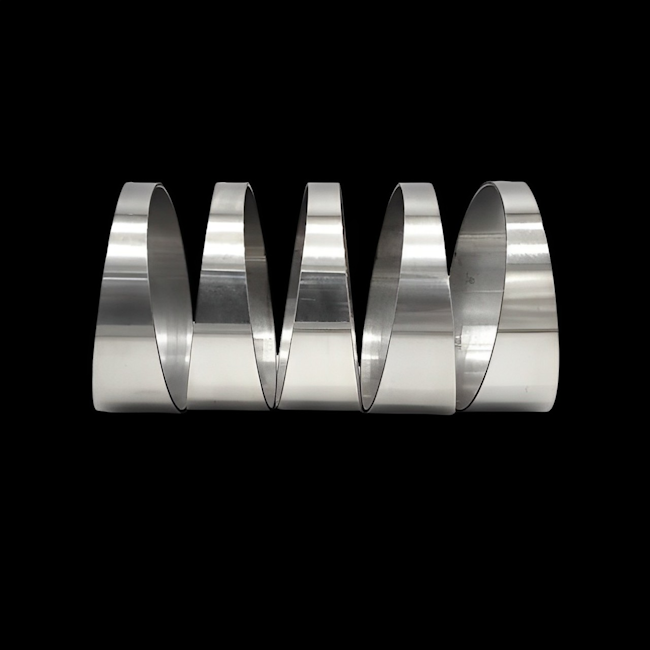

3. Cutting with pipe cutters:

- Advantages: it is a safe and precise method that produces a clean, burr-free cut.

- Disadvantages: can be expensive, especially for large diameter pipes.

Professionals often use pipe cutters to cut stainless steel pipes. This is a hand tool that can be used manually or with electric, hydraulic and pneumatic power. A rotating disc is used by this tool to cut the pipe. When cutting, place the stainless steel pipe near the disc and start cutting. Apply strong pressure while cutting.

Safety precautions are important during the cutting process. Do not swing or apply force to the pipe cutter. Otherwise, the stainless steel pipe may break. The cutting wheel (disc) is susceptible to damage. It is necessary to occasionally monitor the condition of the cutting disc. If the disc is worn out, it must be replaced.

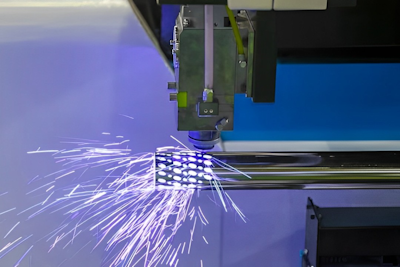

4. Laser cutting:

Overall, laser cutting is a flexible, precise and efficient method for cutting stainless steel tube. It is the best choice for parts that require high build quality, clean cuts without heat, or complex contours. However, laser cutting may not be as cost-effective for small series or simple parts, or for thick tubes.

Overall, laser cutting is a flexible, precise and efficient method for cutting stainless steel tube. It is the best choice for parts that require high build quality, clean cuts without heat, or complex contours. However, laser cutting may not be as cost-effective for small series or simple parts, or for thick tubes.

Advantages:

- Fast, precise and safe method: allows you to get a clean cut without burrs.

- High precision and cutting quality: the laser beam can cut complex contours and holes with high precision, minimal gaps and surface roughness. This makes laser cutting ideal for parts that require high quality assembly.

- Clean cut without heat: unlike other cutting methods, laser cutting does not cause thermal deformation or discoloration of the material. This makes it the best choice for thin-walled pipes that can be deformed or damaged by other methods.

- Safe and environmentally friendly process: laser cutting does not require the use of hazardous liquids or gases, making it safer for the environment and workers.

- Fast and flexible: CNC laser machines can cut tubes of any length and shape quickly and accurately. This makes laser cutting a cost-effective choice for large series and complex parts.

- Wide range of applications: laser cutting can be used to cut pipes made of different grades of stainless steel, as well as other metals such as aluminum, brass and copper.

Flaws:

- High Cost: CNC laser machines are expensive equipment, so laser cutting may not be as cost-effective for small runs or simple parts.

- Pipe thickness: laser cutting is best suited for thin-walled pipes. Thick pipes (over 20mm) can be laser cut, but it can be slower and more expensive.

- Geometry limitations: some complex geometries, such as very small holes or sharp corners, may be difficult or impossible to cut with a laser.

- Necessity of a clean surface: to achieve optimal results, the pipe surface must be clean and free of contaminants.

It is important to note that these are the general advantages and disadvantages of laser cutting stainless steel pipe. Specific advantages and disadvantages may vary depending on the laser, the thickness and grade of the stainless steel pipe, the complexity of the geometry and other factors.

5. Plasma cutting:

- Advantages: this is a fast and efficient method that allows you to cut pipes up to 100 mm thick.

- Disadvantages: may cause deformation of the pipe and formation of burrs.

Plasma cutting is another method of cutting stainless steel pipes. The plasma torch emits a high-temperature plasma jet for cutting. This method of cutting pipes allows for an effective clean, fast and precise cut. Reduction of heat zones during this process. The plasma jet usually consists of a mixture of oxygen and nitrogen or simple nitrogen.

To use a plasma cutter, simply hold it close to the pipe surface and turn it on. The plasma jet itself is suitable for cutting stainless steel pipes. Professionals do not need to apply much force. However, precautions must be taken, as sparks emitted by this plasma jet can cause serious burns if handled carelessly.

Plasma cutting is an effective and versatile method for cutting stainless steel that has many advantages. However, it can be expensive, loud, and can result in warping and harmful emissions. It is important to weigh all of these factors before deciding whether plasma cutting is right for a particular application.

6. Circular saw (cut-off saw):

Advantages:

- Speed: the circular saw can cut stainless steel quickly, especially thick-walled pipes.

- Simplicity: using a circular saw is relatively easy, even for beginners.

- Versatility: circular saws can be used to cut a variety of stainless steel grades.

- Portability: circular saws are usually compact and lightweight, making them easy to transport and use in different locations.

Flaws:

- Inaccuracy: circular saws are not as precise as other stainless steel cutting methods, such as jigsaws or band saws.

- Burrs: cutting stainless steel pipe with a circular saw can result in burrs on the cut edges.

- Overheating: it is important to use the correct blade and cutting speed to prevent the stainless steel from overheating, which can cause damage.

- Sparks: cutting stainless steel with a circular saw can create a lot of sparks, so it is important to wear safety glasses and other protective equipment.

Nowadays, a common method for cutting stainless steel pipes is using a circular saw. This is a hand-held electric saw with a circular blade. With a saw, we can quickly cut stainless steel if we use the right blade. This method for cutting stainless steel pipes uses a high-quality circular saw. This is a hand tool that professionals should handle with care.

After preparation, the specialist must turn on the circular saw. Before use, the circular blade must reach full rotation speed (RPM). After this, the saw is lowered onto the cutting surface. Workers continue to cut stainless steel pipes. But during this process, safety measures are necessary.

7. Band saw:

A band saw is a versatile cutting tool that effectively cuts stainless steel pipes. The teeth of a band saw should be similar to a jigsaw and are made of tungsten carbide to cut stainless steel pipes. Place the blade on the stainless steel pipe and begin cutting. Height adjustment and the use of protective equipment are important, dust masks are worn to prevent inhalation of harmful particles while cutting.

A band saw is a versatile cutting tool that effectively cuts stainless steel pipes. The teeth of a band saw should be similar to a jigsaw and are made of tungsten carbide to cut stainless steel pipes. Place the blade on the stainless steel pipe and begin cutting. Height adjustment and the use of protective equipment are important, dust masks are worn to prevent inhalation of harmful particles while cutting.

Advantages:

- Clean cut: band saws provide clean, precise cuts that require minimal post-cutting work.

- Flexibility: can be used to cut pipes of various shapes and sizes, including round, square, rectangular and oval.

- Accuracy: band saws provide high cutting accuracy, making them ideal for use in applications where precise dimensions are important.

- Versatility: can be used to cut a variety of materials including stainless steel, aluminum, copper, brass and plastic.

- Efficiency: band saws can cut pipes quickly and efficiently, making them a good choice for production environments.

Flaws:

- Cost: band saws can be more expensive than other cutting tools, such as hand saws or metal saws.

- Noise: band saws can be loud, which may make them unsuitable for use in some environments.

- Safety: when using band saws, it is important to follow safety precautions to avoid injury.

- Limited cutting depth: they can only cut to a certain depth, making them unsuitable for cutting thick pipes.

- Cooling needs: when cutting stainless steel, the band saw may become overheated, so you may need to use a coolant.

Choosing the best method for cutting stainless steel pipes depends on several factors, such as:

Pipe diameter:

- For small diameter pipes (up to 25 mm), you can use a grinder or hacksaw for metal.

- For medium diameter pipes (25-50 mm), you can use a grinder, pipe cutters, or a hacksaw for metal.

- For large diameter pipes (more than 50 mm), it is recommended to use pipe cutters, laser or plasma cutting.

Pipe wall thickness:

- For thin-walled pipes (up to 2 mm) you can use a grinder, hacksaw or pipe cutters.

- For thick-walled pipes (more than 2 mm) it is recommended to use pipe cutters, laser or plasma cutting.

Required cutting accuracy:

- If high cutting precision is required, it is recommended to use pipe cutters, laser or plasma cutting.

Budget:

- An angle grinder and hacksaw are the cheapest cutting methods, but they are not always the most accurate.

- Pipe cutters are more expensive, but they provide a more precise cut.

- Laser and plasma cutting are the most expensive methods, but they provide the fastest, most accurate and safest cut.

Regardless of which method you choose, it is important to use the correct tools and technique to avoid injury.

Tips for cutting stainless steel pipes:

- Before cutting, make sure the pipe is free of dust and dirt.

- Use safety glasses, a respirator and gloves.

- Secure the pipe in a vice or clamps to prevent it from moving while cutting.

- Cut the pipe slowly and carefully to avoid overheating the metal.

- After cutting, remove any burrs from the pipe with a file or sandpaper.