Comparison of stainless steel and corrosion-resistant alloys by surface treatment, standards, chemical compatibility, temperature resistance

Comparison

Stainless steel and other corrosion-resistant alloys are widely used due to their resistance to corrosion and chemicals. However, they have certain differences that should be considered when choosing a material.

Key factors for comparison:

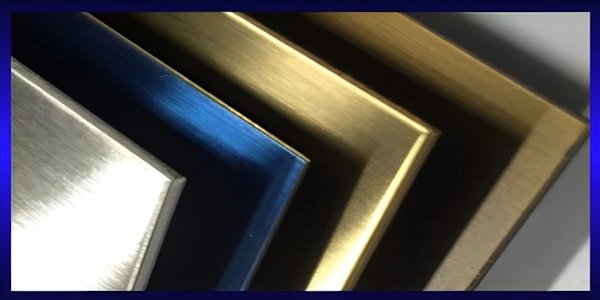

- Surface treatment:

- There are different surface treatment options that affect the appearance, corrosion resistance and other properties. Common options include: sanded, polished, mirrored, satin, etc.

- Standards:

- There are many standards that classify stainless steel by composition, characteristics and application. The most common standards are: AISI (American Iron and Steel Institute), ASTM (American Society for Testing and Materials), EN (European Standard).

- Chemical compatibility:

- Different types of stainless steel react differently to different chemicals. It is important to choose a type of steel that is resistant to the chemicals it will come into contact with.

- Compatibility with other metals and alloys:

- Stainless steel has different compatibility and behaves differently when in contact with different metals and alloys. The corrosion resistance and strength of your structure depend on the right choice of materials.

- Temperature resistance:

- Stainless steel has different resistance to high temperatures. Some types of steel are suitable for use at high temperatures, while others lose their properties when heated.

Stainless steel and corrosion-resistant alloys offer a wide range of properties, making them suitable for a variety of applications. The best choice of material depends on the specific requirements for surface treatment, corrosion resistance, chemical compatibility, and temperature conditions.

Please note that this is only a general overview. For more detailed information on specific materials and their application, it is recommended to consult a specialist.

5 myths about stainless steel

Decided to use stainless steel but heard conflicting opinions? This is not surprising. There are many myths surrounding this material that can be misleading. Let's debunk five of

...Chemical compatibility and resistance of stainless steel

The chemical compatibility and resistance of stainless steel depends on the specific type, grade of steel and the environment with which it comes into contact. There are many different

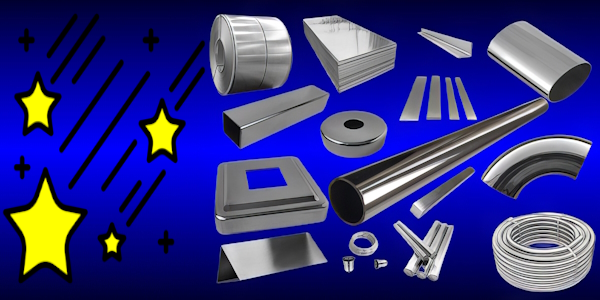

...Classification of stainless rolled metal products

Stainless rolled products in metallurgy (stainless rolled metal products) - products made of stainless steel, obtained on rolling mills by hot, warm or cold

...Compatibility of stainless steel with other metals | Galvanic couple

The compatibility of stainless steel with other metals depends on the specific type/grade of stainless steel and the metal it comes into contact with. Stainless steel is compatible with

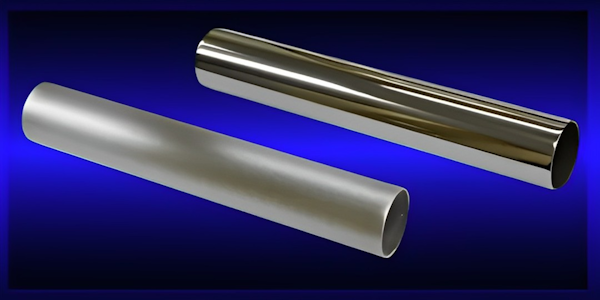

...Differences between matte and mirror stainless steel pipes / tubes

Let's consider the main differences between matte and mirror treatment of the outer surface of a stainless steel pipe and describe the advantages and disadvantages of each. The acquired

...Differences between stainless steel and chrome-plated metals and alloys

In today's industrial world, consumers often face a choice between chromed metals and alloys and stainless steel. This decision is far from trivial, since these materials, although

...Manufacturing equipment for the food industry: why is the choice of stainless steel a matter of safety?

The choice of materials in the food, pharmaceutical, and chemical industries is not just a technical requirement, but a critically important decision that affects the quality,

...Maximum allowable working pressure for stainless steel round welded pipes

Stainless steel welded tubes manufactured in accordance with EN 10357 (DIN 11850) and EN 10217-7 (DIN 17457) can be used for pressure applications at room, low and elevated

...Maximum temperature for some heat-resistant stainless steel grades for use in air

The maximum temperature of stainless steel in air depends on the type of stainless steel and the operating conditions. In general, stainless steels can be used in air at temperatures up

...Stainless steel at home: how to bring durability and style into your house

Stainless steel has long ceased to be merely an industrial material. Thanks to its uniqueness - resistance to corrosion, hygiene, and elegant appearance - it has firmly entered

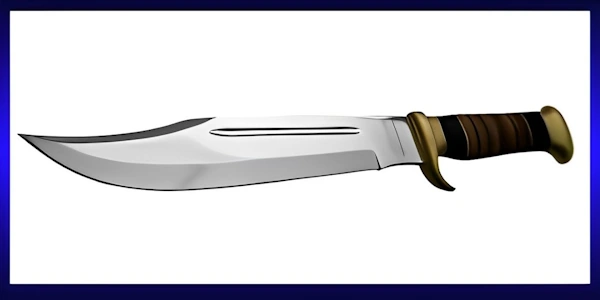

...Stainless steel for knives | Knife steel

Stainless steel for knives is a wide range of alloys that combine corrosion resistance with various properties that make them suitable for the manufacture of knives, blades, blades for

...