Decided to use stainless steel but heard conflicting opinions? This is not surprising. There are many myths surrounding this material that can be misleading. Let's debunk five of the most common ones so you can make the right choice.

Myth 1: Stainless steel never rusts

The truth: The name "stainless steel" is somewhat misleading, as it creates the impression of complete invulnerability. In fact, it would be more accurate to call it corrosion-resistant steel. Its unique property is not the absence of rust, but its ability to self-heal.

The basis of its corrosion resistance is a chemical reaction. When the chromium contained in stainless steel comes into contact with oxygen in the air, it forms a very thin, invisible, and dense layer of chromium oxide on the metal's surface. This layer, called the passive layer, acts as an effective protective barrier, preventing the penetration of moisture and oxygen, which are the main catalysts for rust. If this passive layer is damaged (for example, by a scratch or abrasive action), it quickly regenerates, which is one of the main advantages of stainless steel.

However, under certain extremely aggressive conditions, this protection can be compromised. Such conditions include:

- Prolonged exposure to chlorides: This is most common in seawater or swimming pools, where chlorinated water can cause so-called pitting corrosion.

- Aggressive chemicals: Contact with strong acids or other chemical substances can destroy the passive layer.

- Surface contamination: Particles of ordinary carbon steel that have settled on the surface of stainless steel (e.g., from tools) can cause corrosion, as they do not have a protective layer.

That's why it's important to choose the right grade of stainless steel for a specific environment. For example, for equipment that comes into contact with saltwater, it is better to choose AISI 316, which contains molybdenum and has increased resistance to chlorides, unlike the universal AISI 304.

So, while stainless steel is extremely resistant to corrosion, it is not completely invulnerable. Conscious use and proper material selection are the keys to its longevity.

Myth 2: All grades of stainless steel are the same

The truth: This is one of the most important myths to remember. There are over 150 different grades of stainless steel, and each has a unique chemical composition that determines its properties. The most popular grades are AISI 201, AISI 304, AISI 316, and AISI 430.

- AISI 201: This grade was developed as a more affordable alternative to 304. Part of the expensive nickel is replaced with manganese. This makes the steel cheaper, but unfortunately, less resistant to corrosion, especially in aggressive environments. It has higher hardness and strength, making it ideal for the production of kitchen utensils, decorative elements, and parts that do not come into contact with chemicals or seawater.

- AISI 304: This is the "workhorse" in the world of stainless steel. Its composition includes about 18% chromium and 8% nickel. Nickel makes it extremely corrosion-resistant and flexible in manufacturing. AISI 304 is ideal for most household and industrial needs, such as kitchen equipment, sinks, pipes, and utensils.

- AISI 316: This grade contains molybdenum, which significantly increases its corrosion resistance. It is indispensable in aggressive environments, for example, for equipment in the chemical industry, on ships, or in swimming pools with chlorinated water.

- AISI 430: This grade belongs to another family - ferritic steels. Unlike 304 and 201, it does not contain nickel but has a high chromium content (about 17%). Because of this, 430 steel is magnetic and significantly cheaper. It is used in indoor equipment where there is no risk of corrosion: for example, in refrigerator casings, dishwashers, range hoods, and decorative elements. It is not suitable for outdoor use or for contact with aggressive liquids.

Choosing the wrong grade can lead to rapid wear or damage, so always consult with specialists. Understanding these differences is key to successfully selecting a material that will serve you for a long time and effectively. Not all stainless steels are created equal.

Myth 3: Stainless steel is not magnetic

The truth: This is one of the most common myths that leads to false conclusions. In reality, the magnetic properties of stainless steel depend on its crystalline structure, not its quality or chromium content. Using a magnet to check is a test of the steel type, not its ability to resist corrosion.

Let's consider the three main groups of stainless steel:

- Austenitic steels: This is the most common group, which includes grades AISI 304 and AISI 316. In their normal state, they are non-magnetic. Their non-magnetic nature is due to the high content of nickel (in the case of 304 and 316) or manganese (in the case of 201), which stabilizes the austenitic structure. However, if such steel is subjected to cold mechanical processing (e.g., bending, stamping, drawing), its structure can partially transform into martensitic, which gives it weak magnetic properties. Therefore, a magnet may be weakly attracted to the bending points, but this does not indicate low quality.

- Ferritic steels: This group includes the grade AISI 430. They contain chromium but no nickel, which makes them significantly cheaper. The ferritic structure of the steel is always magnetic, so a magnet will be strongly attracted to such products. These steels are used for indoor equipment where corrosion resistance is not critically important, for example, in dishwashers, decorative panels, or range hood elements.

- Martensitic steels: These steels are also magnetic. They contain a high carbon content, which makes them very hard and suitable for hardening. Therefore, they are used for making cutting tools - knives, surgical scalpels.

So, if your magnet doesn't stick to a kitchen sink, it most likely means it's made of AISI 304. And if it's attracted to a knife, it's probably martensitic steel. The conclusion is simple: a magnet is not a "detector" of stainless steel quality, but merely a tool that helps determine its structural type.

Myth 4: Stainless steel is too expensive

The truth: Although the initial cost of stainless steel is indeed higher than that of ordinary carbon steel, this does not account for its long-term value and cost-effectiveness. Stainless steel is an investment that pays off over time due to its unique properties.

The main factors that make stainless steel a profitable long-term choice:

- Durability: Stainless steel products last for decades without losing their properties and appearance. Unlike other metals, it is not prone to corrosion or decay. This means you won't have to spend money on replacement or repairs.

- Low maintenance costs: Stainless steel does not require painting, anti-corrosion coating, or other regular procedures to protect against rust. A simple cleaning with water is enough to keep it in perfect condition. This significantly reduces operating costs over its entire service life.

- Energy efficiency: In industry, for example, in the food or chemical sectors, stainless steel is used because of its smooth surface, which reduces friction. This, in turn, helps to reduce energy consumption for pumping liquids.

Let's consider a simple example. If you choose between a carbon steel fence that needs to be regularly painted and a stainless steel fence, the initial cost for the latter will be higher. However, over 5-10 years, the cost of paint, solvents, and labor for the carbon steel will exceed the price difference. Thus, the total cost of its use in the long run turns out to be much lower.

It is a profitable investment that saves you money in the future.

Myth 5: Stainless steel requires no maintenance

The truth: Although stainless steel is extremely resistant to external influences, like any other material, it requires minimal but regular care. The accumulation of dirt, dust, grease, chlorides, or salt solutions on the surface can eventually damage the protective layer and lead to the appearance of stains or even rust.

Simple regular care will help maintain its aesthetic appearance and protective properties for many years.

Maintenance recommendations:

- Regular cleaning: The best way to care for it is to regularly wipe the surface. Use a soft cloth or sponge with soapy water, and then rinse off the residue with clean water.

- Use of special products: For stubborn dirt (e.g., fingerprints or grease stains), you can use special stainless steel cleaning products. They create a protective film that adds shine and helps repel dirt.

- Correct direction: Always clean the surface along the grain (if any). Wiping against the grain can leave visible scratches.

- Avoid aggressive substances: Never use abrasive cleaning powders, metal brushes, or products containing chlorine, ammonia, or other aggressive chemicals. They can damage the protective layer and lead to corrosion.

Remember that stainless steel is a durable material, but proper care will help maintain its perfect condition and avoid unnecessary problems in the future.

Conclusion

Stainless steel is more than just a metal. It is a technological material with unique properties that make it ideal for various fields, from everyday life to industry. However, like any complex material, it is shrouded in myths that can be misleading.

All the debunked myths boil down to one thing: informed choice and proper care are the keys to the longevity of stainless steel. You should not think that stainless steel is invulnerable to rust or requires no maintenance. On the contrary, it is the understanding of its types (AISI 201, 304, 316, 430), their properties, and operating rules that will allow you to fully benefit from its advantages.

Thanks to its corrosion resistance and low operating costs, stainless steel is a profitable investment in the long run. Knowing its features helps to save money, avoid mistakes in selection, and keep products in perfect condition for many years.

Stainless Steel Round Pipe

Stainless Steel Round Pipe  Stainless Steel Square Pipe

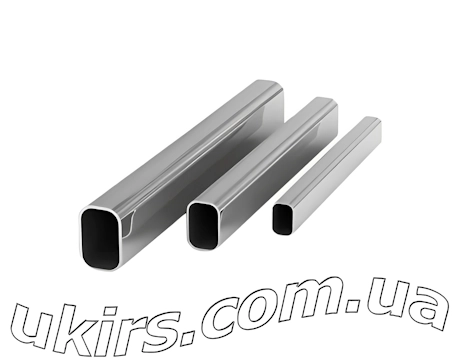

Stainless Steel Square Pipe  Stainless Steel Rectangular Pipe

Stainless Steel Rectangular Pipe  Stainless Steel Oval Pipe

Stainless Steel Oval Pipe  Stainless Steel Elbow

Stainless Steel Elbow  Stainless Steel Decorative Cover

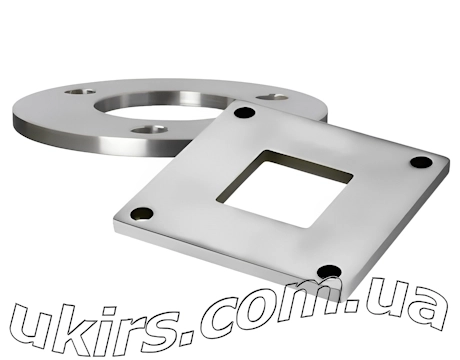

Stainless Steel Decorative Cover  Stainless Steel Flange

Stainless Steel Flange  Stainless Steel Plug / Cap

Stainless Steel Plug / Cap  Stainless Steel Handrail Holder

Stainless Steel Handrail Holder