N685 is a stainless martensitic chromium steel with a high carbon content, addition of molybdenum and vanadium. N685 steel is an excellent choice for those looking for a strong, durable and sharp knife. Its characteristics make it popular among both professionals and amateurs.

Characteristics

- Viscosity and plasticity: good;

- Wear resistance: very high;

- Machinability: good;

- Dimensional accuracy: good;

- Suitability for polishing: good;

- Corrosion resistance: high.

Chemical composition

Chemical composition of steel grade N685 | ||||||

| C | Cr | Mo | V | Mn | Si | Fe |

| 0,9 | 17,5 | 1,1 | 0,1 | 0,4 | 0,45 | Other |

Application

- Hot runner systems;

- Molds;

- Food industry such as extrusion screws, can sealing rollers, etc.;

- Pharmaceutical industry such as punches and dies for tablet presses;

- Extrusion screws for plastic processing;

- Other.

Heat treatment

Typically N685 stainless steel is supplied in annealed condition with a maximum hardness of 265 HB.

Heat treatment of steel N685 | ||

| Stress relieving | ||

| Temperature | max. 650 °C | Soft annealed material: for stress relief annealing after mechanical processing, hold the material at temperature in a neutral atmosphere for 1-2 hours after complete heating, then slowly cool the furnace at 20 °C [68 °F]/hour to 200 °C [392 °F], then cool in air. |

| Temperature | Hardened and tempered material: the temperature for stress relief annealing should be approx. 50 °C [122 °F] below the previously selected tempering temperature. Other procedure as for stress relief annealing of soft annealed material. | |

| Hardening and Tempering | ||

| Temperature | 1,000 to 1,050 °C | For hardening, hold the material at the specified temperature for 15-30 minutes after complete heating and quench quickly. Cool the material to approx. 30 °C [86 °F]. Tempering should take place immediately. |

| Temperature | 100 to 200 °C | Tempering treatment to the desired working hardness after hardening - see tempering diagram. Heat the material slowly and temper once for 1 hour/20mm material thickness, but at least 2 hours. After the heat treatment step, the material must be cooled to approx. 30 °C [86 °F]. |

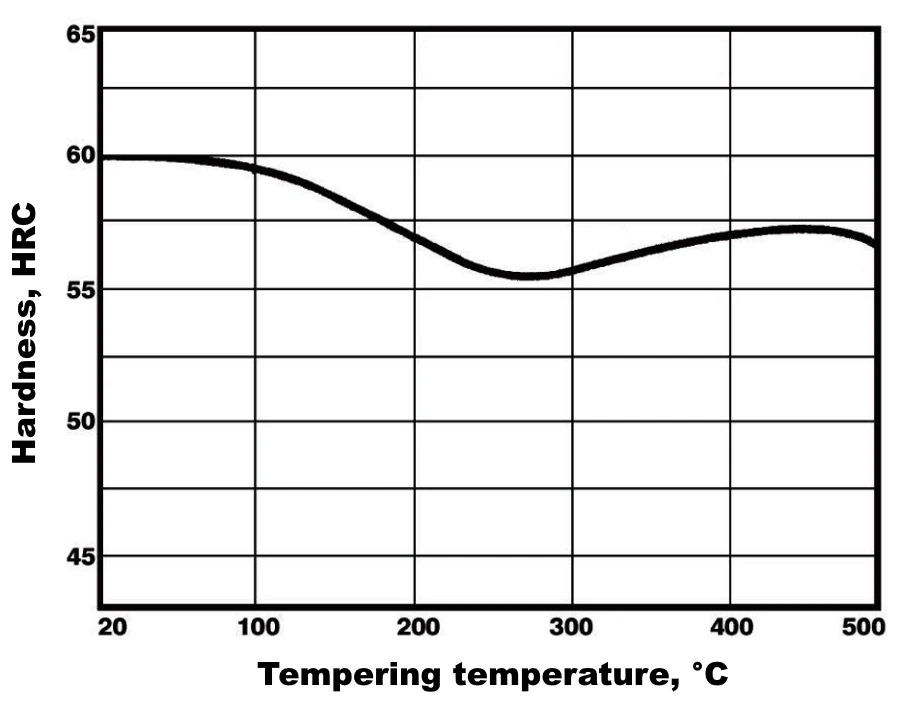

Tempering chart

- Hardening temperature: 1030 °C / 1886 °F;

- Specimen size: square 20 mm;

- Hardness up to 57 - 59 HRC.

Physical properties

| Temperature °C | 20 |

| Density (kg/dm³) | 7.7 |

| Thermal conductivity (W/(m.K)) | 15 |

| Specific heat (kJ/kg K) | 0.43 |

| Spec. electrical resistance (Ohm.mm²/m) | 0.8 |

| Modulus of elasticity (10³N/mm²) | 215 |

Thermal Expansions between 20°C | 68°F and ...

| Temperature °C | 100 | 200 | 300 | 400 | 500 |

| Thermal expansion (10⁻⁶ m/(m.K)) | 10.4 | 10.8 | 11.2 | 11.6 | 11.9 |

N685 is a high-quality stainless steel that is often used to produce knives and other tools that require high strength and corrosion resistance. This alloy has a number of characteristics that make it a popular choice among manufacturers.