N690 is a cobalt-alloyed martensitic stainless steel produced by Böhler - Uddeholm AG. The steel has an original chemical composition that stands out from other grades of similar steels. One of the main differences of N690 (bohler) stainless steel is that it contains 1.5% cobalt, which increases the heat resistance of the steel and has a strong effect on its mechanical properties.

In conditions of exposure to non-aggressive environments, products made of this alloy are not subject to destructive processes. At the same time, the hardness of the metal is significantly increased due to the hardening. Nominally, N690 steel is hardened to values in the region of 60 - 63 HRC.

Similar in chemical composition or analogous to this steel grade is Japanese VG-10, but it contains, compared to N690, more molybdenum and chromium. Also similar in chemical composition and properties are AUS-10 (Japan), Z100CD17 (France).

Application

- Packaging; Food industry, such as extrusion screws, can seamers;

- Injection molding screws and check valves;

- Cutting tools and knives;

- Injection molds for plastics;

- Pharmaceutical industry, such as tablet punches and dies;

- Extrusion screws for plastics processing and screws for processing glass fiber reinforced plastics;

- Hot runner systems.

Advantages of N690 stainless steel

N690 steel is used to produce knives and is considered one of the best materials for their manufacture. The advantages and obvious benefits of N690 steel include:

- High strength and resistance to physical loads;

- Resistance to bending and fracture loads;

- Resistance to twisting;

- Excellent cutting properties;

- Excellent resistance to blunting and long-term sharpness retention;

- Strength and ductility: good;

- Wear resistance: very high;

- Machinability: good;

- Dimensional stability: good;

- Suitability for polishing: good;

- Corrosion resistance: high;

- Other.

Chemical composition

Chemical composition of steel grade N690 | |||||||

| C | Cr | Mo | V | Co | Mn | Si | Fe |

| 1,08 | 17,3 | 1,1 | 0,1 | 1,5 | 0,4 | 0,4 | Other |

Heat treatment

Typically N690 stainless steel is supplied in annealed condition with a maximum hardness of 285 HB.

Heat treatment of steel N690 | ||

| Stress relieving | ||

| Temperature | max. 650 °C | Soft annealed material: for stress relief annealing after mechanical processing, hold the material at temperature in a neutral atmosphere for 1-2 hours after complete heating, then slowly cool the furnace at 20 °C [68 °F]/hour to 200 °C [392 °F], then cool in air. |

| Temperature | Hardened and tempered material: the temperature for stress relief annealing should be approx. 50 °C [122 °F] below the previously selected tempering temperature. Other procedure as for stress relief annealing of soft annealed material. | |

| Hardening and Tempering | ||

| Temperature | 1,030 to 1,080 °C | For hardening, hold the material at the specified temperature for 15-30 minutes after complete heating and quench quickly. Cool the material to approx. 30 °C [86 °F]. Tempering should take place immediately. |

| Temperature | 100 to 200 °C | Tempering treatment to the desired working hardness after hardening - see tempering diagram. Heat the material slowly and temper once for 1 hour/20mm material thickness, but at least 2 hours. After the heat treatment step, the material must be cooled to approx. 30 °C [86 °F]. |

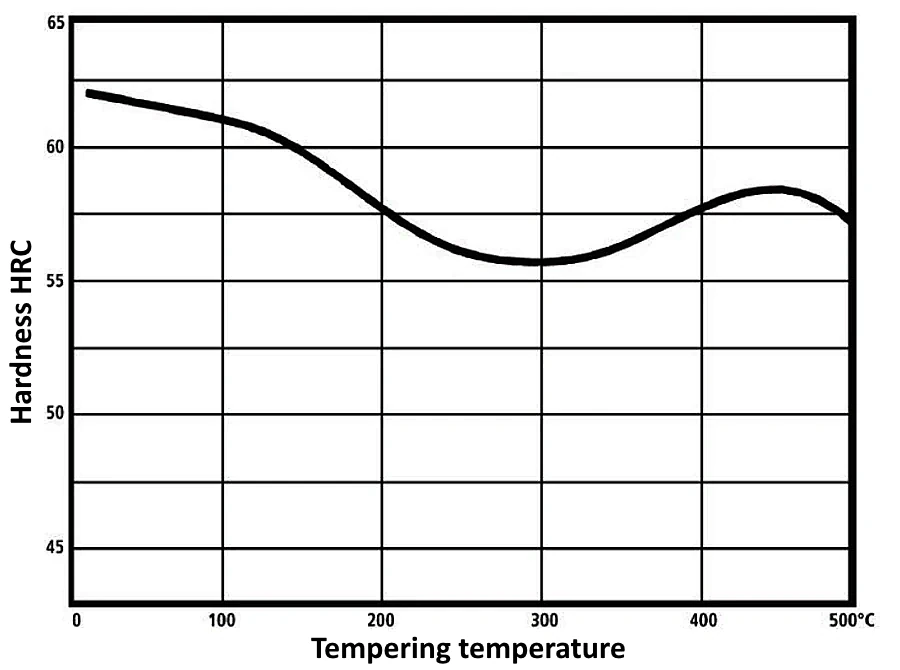

Tempering chart

- Hardening temperature: 1030 °C / 1886 °F;

- Tempering: 2x2h;

- Sample cross-section: square 20mm;

- Hardness up to 59-61 HRC.

Physical properties

| Temperature °C | 20 |

| Density (kg/dm³) | 7.7 |

| Thermal conductivity (W/(m.K)) | 15 |

| Specific heat (kJ/kg K) | 0.43 |

| Spec. electrical resistance (Ohm.mm²/m) | 0.8 |

| Modulus of elasticity (10³N/mm²) | 223 |

Thermal expansions between 20°C | 68°F and ...

| Temperature °C | 100 | 200 | 300 | 400 | 500 |

| hermal expansion (10⁻⁶ m/(m.K)) | 10.4 | 10.8 | 11.2 | 11.6 | 11.9 |

N690 steel has high strength, which allows it to withstand harsh operating conditions without compromising its integrity.