Duplex stainless steel

Duplex

Duplex stainless steel - is an alloy with a mixed ferritic-austenitic structure. The chromium content in such a grade is at the level of 18 - 28%, nickel within 4.5 - 8%. Additional alloying elements in them are molybdenum, copper, titanium, niobium. The chemical composition of these stainless steel grades is balanced so that the ratio of austenite and ferrite after optimal heat treatment is approximately 1 to 1. This class of steel grades has an advantage in strength of 1.5 - 2 times compared to austenitic steel with satisfactory ductility and resistance to impact loads.

Duplex Stainless Steel Frequently Asked Questions

- increased resistance to corrosion;

- high mechanical strength;

- better wear resistance, etc.

The idea of creating such steels originated in the 1920s in France and Sweden. The first smelting was carried out in the Swiss city of Avesta in 1930. The first brand of duplex steel was patented in 1936.

The main reasons for the emergence and increased production of duplex and superduplex steels also include:

- improvement of technology for regulating nitrogen content in steels;

- nickel deficiency;

- rising cost of austenitic steels;

- increased demand as a result of the active construction of oil platforms and rigs, which require steels with increased resistance to corrosion in sea salt water.

- increased resistance to pitting and crevice corrosion;

- increased resistance to stress corrosion cracking;

- good corrosion resistance to sulfide stress;

- high mechanical strength;

- good weldability;

- ease of processing;

- low thermal expansion;

- high energy absorption and thermal conductivity;

- increased resistance to corrosion fatigue;

- wear resistance.

Due to the low content of expensive nickel in the composition, the price of duplex is more affordable, which is very important for modern industry.

- in the oil and gas industry;

- in the chemical and food industries;

- in pulp and paper production;

- in energy;

- in shipbuilding;

- in mechanical engineering;

- in aviation;

- in the production of equipment and apparatus for working in sulfuric and hydrochloric acids;

- in the production of equipment for seawater desalination;

- in the production of heat exchangers, water heaters, rotors and pressure vessels;

- in the production of tanks for the transportation of chemical products;

- in the production of fire protection partitions on oil platforms;

- it is used to produce reinforcement for metal structures, sheets, strips, angles, wire, etc.

The application of rolling or bending technologies to two-phase duplex steel with a thickness of 7.5 to 10 cm and more may be ineffective, since many grades of duplex steels have a shape memory effect.

List of duplex stainless steel grades

List of stainless steel grades that are duplex type. To get detailed information about a specific grade, follow the link from the list.

Stainless Steel Grade AISI 318 | EN 1.4462 | X2CrNiMoN22-5-3

AISI 318 | EN 1.4462 | X2CrNiMoN22-5-3 belongs to the family of duplex stainless steels. It is characterized by an excellent combination of corrosion resistance and strength. The

...Stainless Steel Grade AISI 329 | EN 1.4460 | S31200 | X3CrNiMoN27-5-2

Stainless steel AISI 329 | EN 1.4460 | S31200 | X3CrNiMoN27-5-2 Duplex is an acid-resistant austenitic-ferritic steel that exhibits very good corrosion resistance, especially in

...Stainless Steel Grade EN 1.4162 | S32101 (2101) | X2CrMnNiN21-5-1

EN 1.4162 | X2CrMnNiN21-5-1 - duplex stainless steel, which demonstrates better corrosion resistance. It is characterized by high resistance to cracking, better fatigue

...Stainless Steel Grade EN 1.4362 | S32304 (2304) | X2CrNiN23-4

EN 1.4362 | X2CrNiN23-4 is a low-carbon and high-alloy stainless steel with a nickel content of less than 4%. The steel has a ferritic-austenitic structure, so it is called duplex

...Stainless Steel Grade EN 1.4410 | F53, S32750 | DIN X2CrNiMoN25-7-4

Super Duplex EN 1.4410 | F53, S32750 | DIN X2CrNiMoN25-7-4 is a duplex stainless steel specially developed for operation in aggressive chlorine-containing environments. It has

...Stainless Steel Grade EN 1.4482 | S32001 (2001) | X2CrMnNiMoN21-5-3

EN 1.4482 | S32001 (2001) | X2CrMnNiMoN21-5-3 is a high quality duplex stainless steel. When properly heat treated it has a microstructure with a nearly equal proportion of

...Stainless Steel Grade EN 1.4501 | S32750 | X2CrNiMoCuWN25-7-4

EN 1.4501 | S32750 | X2CrNiMoCuWN25-7-4 - duplex stainless steel with excellent properties: impact toughness, high strength, corrosion resistance to a large number of organic and

...

Stainless Steel Round Pipe

Stainless Steel Round Pipe  Stainless Steel Square Pipe

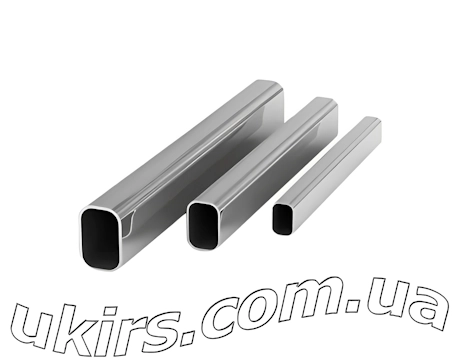

Stainless Steel Square Pipe  Stainless Steel Rectangular Pipe

Stainless Steel Rectangular Pipe  Stainless Steel Oval Pipe

Stainless Steel Oval Pipe  Stainless Steel Elbow

Stainless Steel Elbow  Stainless Steel Decorative Cover

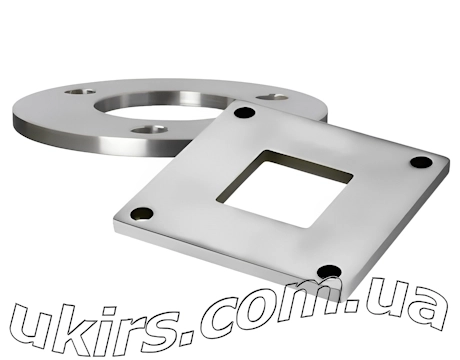

Stainless Steel Decorative Cover  Stainless Steel Flange

Stainless Steel Flange  Stainless Steel Plug

Stainless Steel Plug  Stainless Steel Handrail Holder

Stainless Steel Handrail Holder