Atmospheric corrosion of stainless steel is the process of destruction of stainless metal due to its interaction with air, water and other substances in the ground atmosphere. A feature of atmospheric corrosion is the possibility of free access of oxygen to the corroding surface. This is due to the small thickness of the oxide film and convection of electrolyte mixing.

Stainless steels are widely used as architectural and construction materials due to their high degree of corrosion resistance, unique aesthetic quality and stability in unpolluted atmospheric environments. Although stainless steel is very resistant to corrosion, localized corrosion can occur in certain environments, especially in marine atmospheric conditions, if the appropriate grade / brand of stainless steel is not used.

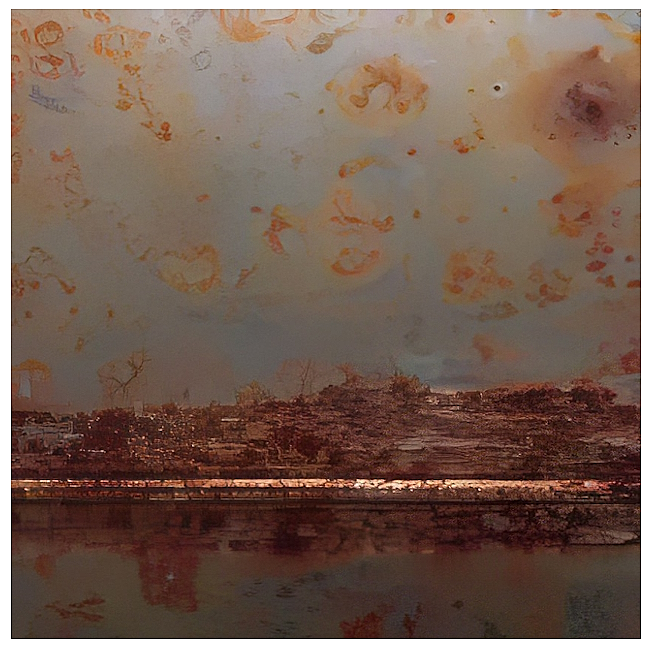

Exposure to an aggressive environment on stainless steel can damage not only the aesthetic appearance of the structure, but can even put it out of service or cause irreparable damage to the strength of the supporting structure.

Selecting the appropriate grade of stainless steel requires some knowledge, as it must be matched to the actual location of the structure and the atmospheric conditions that will surround it. In terms of material selection, austenitic stainless steel grade AISI 316/316L has proven to be a very popular choice for architectural applications in many locations, but it is not always suitable for demanding locations such as the marine environment in the Middle East. In such cases, the use of a high-performance grade, often combined with good surface treatment and established cleaning procedures, is necessary to maintain clean surfaces.

The rate of atmospheric corrosion of stainless steel depends on climatic factors: humidity and air temperature. Concentrations of such impurities as sulfur oxides, nitrogen oxides, chemical production emissions and other atmospheric pollutants also affect the rate of corrosion.

What are the types / kinds of atmospheric corrosion of stainless steel ?

Atmospheric corrosion of stainless steel is usually divided into dry, damp and wet depending on the degree of surface moisture. Wet and damp corrosion proceeds by an electrochemical mechanism, while dry corrosion proceeds by a chemical mechanism.

Dry atmospheric corrosion

Dry atmospheric corrosion is observed when there is no moisture film on the surface of stainless metal. If the relative air humidity is 60% or less, dry atmospheric corrosion occurs. The mechanism of corrosion destruction is chemical. Protective oxide films are formed on the surface, inhibiting the corrosion process.

At first the process proceeds quite quickly (formation of a thin oxide film), then it slows down considerably and a constant very low corrosion rate is established. This phenomenon is caused by the low ambient temperature. A thin oxide film forms on the metal almost immediately or within a few hours, which leads to surface darkening. The maximum thickness of the moisture layer during dry atmospheric corrosion is insignificant. If the atmosphere contains admixtures of aggressive gases, such as, for example, sulfur gases, then the corrosion rate increases significantly.

Wet atmospheric corrosion

Wet atmospheric corrosion is observed when there is a thin film of moisture on the surface. The thickness of such a film is up to 1 µm. The relative humidity of the air, when the formation of a wet film begins, is about 60 - 70%. The value at which condensation of moisture on the surface begins is called critical humidity. Critical humidity depends on air pollution and the state of the metal. Condensation of moisture occurs by a capillary, chemical or adsorption mechanism.

Capillary condensation of moisture

Capillary condensation of moisture is observed in cracks, crevices, and crevices on the metal surface, pores in the film of corrosion products, under contamination, etc.

Chemical condensation of moisture

Chemical condensation of moisture occurs when corrosion products interact with atmospheric moisture, resulting in rust that retains this moisture.

Adsorption condensation of moisture

Adsorption condensation of moisture occurs as a result of the manifestation of adsorption forces on the surface of the metal.

Wet atmospheric corrosion

Wet atmospheric corrosion occurs at a relative air humidity of about 100%, when moisture collects on the surface in the form of clearly visible drops or when the structure is directly exposed to rain or fog. Wet atmospheric corrosion is also observed on structures that are doused with water or completely submerged. With wet corrosion, the moisture film is more than 1 mm. An increase in the concentration of impurities in the water film stimulates corrosion.

Factors of atmospheric corrosion of stainless steel

The rate of atmospheric corrosion of stainless steels depends on the presence or absence of certain factors.

Characteristics of stainless steel

The characteristics of the stainless steel grade can affect the resistance to atmospheric corrosion. The content of alloying elements, surface treatment, and weld treatment are very important factors that affect the ability of stainless metal to resist atmospheric corrosion.

Air humidity during atmospheric corrosion

The presence of water on the surface of a stainless steel metal structure significantly increases atmospheric corrosion. Moisture most often comes as precipitation through rain, fog. With increasing temperature, the relative humidity value decreases.

There is a critical value of atmospheric humidity. And for each grade/alloy of stainless steel, this is its own specific number. If the relative humidity of the air is within the limits acceptable for a certain grade of stainless steel, then the corrosion destruction of such grades is insignificant or absent altogether. If it is higher, then increased destruction begins. In a heavily polluted atmosphere (for example, a technological environment), the concept of critical humidity is not always applied and plays a significant role, since the corrosion process is significantly enhanced by harmful impurities in the atmosphere.

Atmospheric impurities (gases)

Pollution of the atmosphere with gases sharply increases the rate of corrosion. A very aggressive environment is the technological environment near large industrial enterprises, which constantly emit harmful impurities into the atmosphere. The presence of such compounds significantly increases the rate of atmospheric corrosion of certain grades of stainless steel.

Sulfur dioxide (SO2) has a very strong effect. Its low concentration increases the corrosion rate by tens and hundreds of times. In high concentrations, the rate of atmospheric corrosion does not increase so much (only 5-7 times). This component is formed during the combustion of coal, gasoline, and oil.

Gases, getting on the moisture film on the surface of the metal structure, increase the electrical conductivity of the film. SO2 and Cl2 act as cathode depolarizers, SO3 and HCl increase the absorption capacity of corrosion products, NH3 acts as a complexing agent, SO2 and HCl are depassivators.

The presence of sulfuric acid in the atmosphere greatly increases the rate of corrosion of stainless steel. This is especially true for metals that are unstable in it - iron, nickel.

Particulate matter in the atmosphere

Hard active or passive particles fall from the atmosphere to the surface. They can act as depassivators, complexing agents, increase the electrical conductivity of the moisture film and the absorption capacity (hygroscopicity) of corrosion products, facilitate capillary condensation of moisture (inert material such as sand). Hard particles such as Na2SO4, NaCl, (NH4) 2SO4, coal particles, various carbon compounds, metal oxides and others are found in the atmosphere. These substances in the form of hard particles or dust contact the wet surface of the metal structure, form galvanic cells, intensifying corrosion. Therefore, dust-free air is much less active than the atmosphere polluted with various particles.

Geographical factor

Humidity, air pollution, and temperature vary in different geographical locations. Air humidity has the greatest impact on atmospheric corrosion. It has been established that in regions with constantly high humidity, corrosion processes occur more intensively. The main influence is not the number of rainy days, but the time the moisture film remains on the metal surface. In deserts, where air humidity is very low, the oxide film on the surface of stainless steel products is quite stable and the products remain shiny for a long time.

Ambient temperature

As the temperature of the external environment increases, the process of atmospheric corrosion slows down. The moisture covering the surface of the metal product evaporates, the absolute humidity of the air decreases. As the temperature decreases, the opposite happens. The relative humidity of the environment increases, promoting condensation of moisture. The rate of atmospheric corrosion of stainless steel increases.

Features of atmospheric corrosion of stainless steel

The metal surface is covered with a thin film of electrolyte. The electrolyte can be either the wet itself or the corrosion products that have absorbed moisture.

A feature of atmospheric corrosion of stainless steels is the possibility of free access of oxygen to the corroding surface. This is due to the small film thickness and convection of electrolyte mixing. Therefore, even in acidified electrolytes, atmospheric corrosion occurs with oxygen depolarization.

Also, due to the thin layer of moisture on the corroding surface of the metal, the anodic process is difficult, while the cathodic process, on the contrary, is facilitated.

When galvanic pairs operate, a small thickness of the moisture film also plays a role - the ohmic resistance of the electrolyte increases.

Atmospheric corrosion of stainless alloys occurs with anodic-tocodic-ohmic control. But depending on some conditions (thickness, electrical conductivity of the moisture film, its composition, the nature of the alloy), anodic-tocodic-ohmic control can change into predominantly anodic, preferably cathodic or ohmic.

Addition of a certain amount of nickel, chromium, aluminum, titanium to the stainless steel composition - transfers the surface of the stainless steel to a passive state. Addition of copper (cathode additive) and phosphorus - inhibits the anodic reaction.

How to ensure protection of structures from atmospheric corrosion ?

The correct selection of the grade of stainless steel for specific operating conditions of stainless steel products and structures will be the best protection against the destructive effects of atmospheric corrosion. Also important for counteracting corrosion is the surface treatment of stainless metal. The smoother the shiny polished surface of your product, the more resistant it is to negative atmospheric factors. No less important is the correct treatment of welds.