Stainless rolled products in metallurgy (stainless rolled metal products) - products made of stainless steel, obtained on rolling mills by hot, warm or cold rolling.

Assortment - a set of rolled profiles (cross-sectional shape of a rolled product) that differ in shape and size.

Stainless rolled metal products, represented by a variety of different stainless steel products, are in high demand in various industries and everyday life.

Classification of stainless rolled metal products by grades

According to grades of stainless steel, it is divided into five main groups, which are represented by the following steels :- austenitic

The austenitic group includes non-magnetic metals. They contain nickel, which contributes to a significant increase in the anti-corrosion properties of stainless steel. Such a metal is able to successfully resist corrosion even at high temperatures.- ferritic

The ferrite group is represented by magnetic metals with a reduced carbon content and an increased chromium content. Ferrite steels, along with austenitic steels, are among the most commonly used types of stainless steel.- duplex

Duplex stainless rolled metal is a transitional link between the austenitic and ferritic groups, since it is characterized by an austenitic-ferritic structure. Duplex rolled metal is usually used in environments with increased chloride content.- martensitic

Martensitic stainless steels are also magnetic. They contain both carbon and chromium, up to twelve percent of the total mass. Martensitic steels are widely used in mechanical engineering, as well as for making cutlery and many other household items.- reinforced

The composition of hardened stainless metals is very diverse: they contain nickel, niobium, and copper, and the chromium content is seventeen percent, which leads to good anti-corrosion properties of this type of rolled metal.Classification by shape

flat

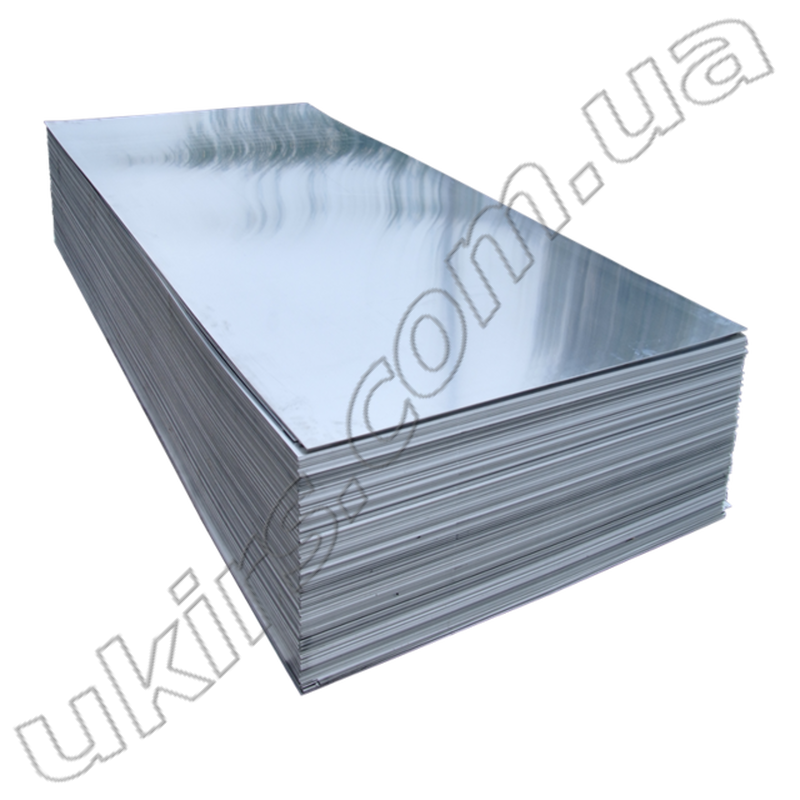

Flat stainless steel products include rolls and sheets.Roll

Stainless steel roll - a cylindrical roll of any flat thin stainless metal. It is produced in the form of a tape wound on a rigid shaft or sleeve. It has a constant width. According to the manufacturing method, it is divided into hot-rolled, cold-rolled.

Sheet

Stainless steel sheet - can have different thickness and cutting, surface treatment. It is made from slabs (blanks) or from a roll on special equipment by cutting ("slicing"). Division by manufacturing method: hot-rolled, cold-rolled.

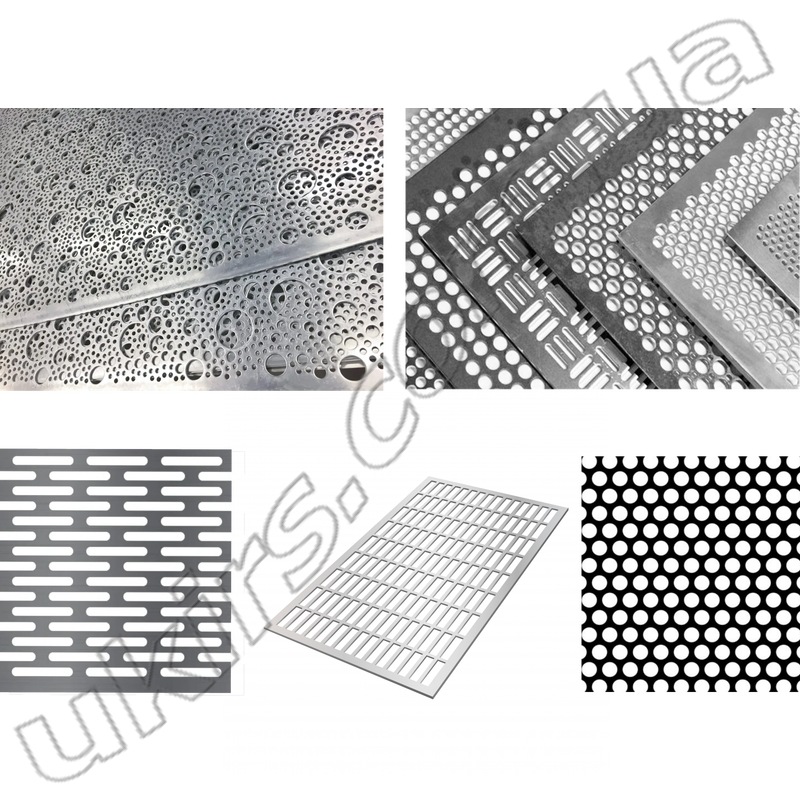

Perforated sheet

Stainless steel perforated sheet is a flat sheet with holes in its plane. Modern technologies allow to produce such sheets with any size and shape of holes and simultaneously combine several forms.

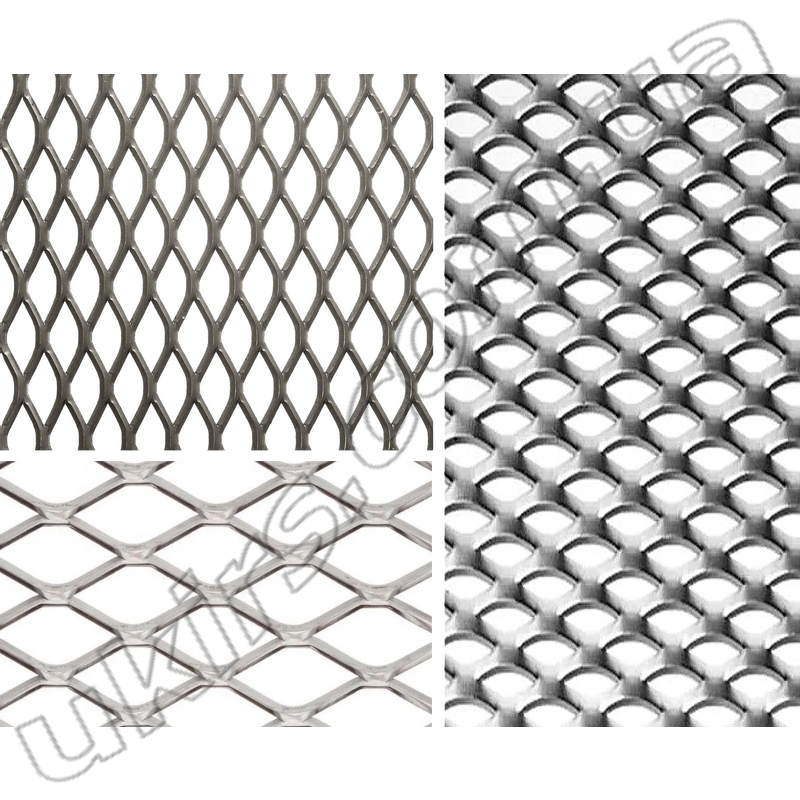

Expanded metal sheet

Stainless steel sheet expanded metal is produced by cutting and stretching a metal sheet on special equipment. This type of processing is more economical compared to other possible metalworking methods, since there is practically no metal waste.

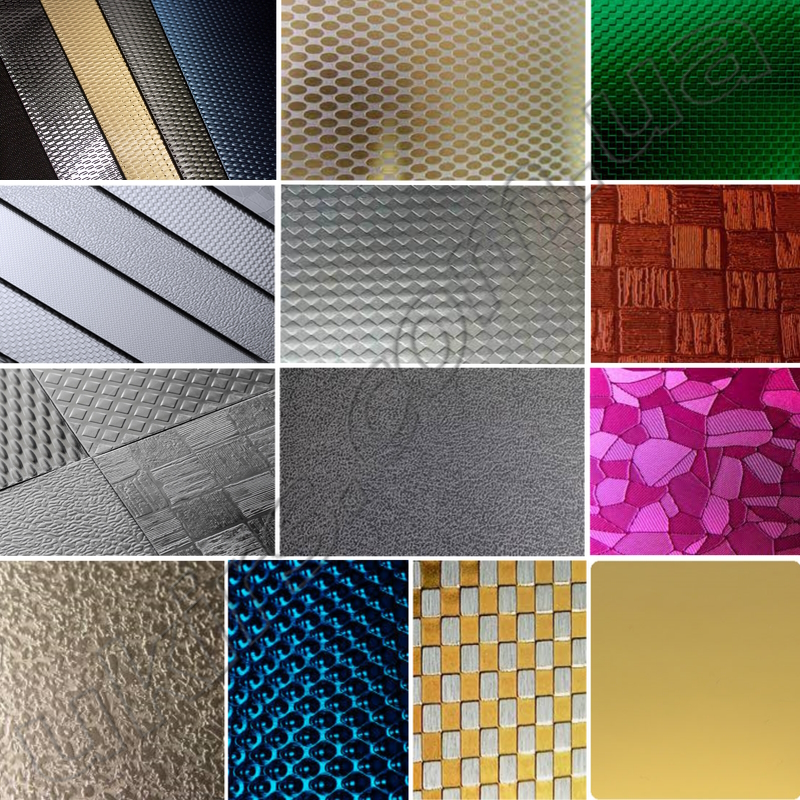

Corrugated sheet

Stainless steel corrugated sheet is a rolled sheet of stainless metal, on which a relief pattern of patterns called "riffles" is applied. The type of pattern, the size of the riffles and their location can be different. It is produced by hot rolling or embossing.

Decorative leaf

Decorative stainless steel sheet is a flat sheet of stainless steel with a characteristic pattern. As a rule, the pattern is applied to one front side. Cutting-edge technologies make it possible to produce hundreds, if not thousands, of variations of such a fantastic-looking sheet.

varietal

Simple - circle (rod), square, hexagon, strip.Rod (circle)

Stainless steel round (rod, round bar) is one of the many types of rolled metal products that have a constant round cross-section. It is produced by hot or cold rolling.

Square

Stainless Rod (circle) stainless square is a type of rolled metal product that consists of square cross-section stainless steel rods produced by hot and/or cold rolling.

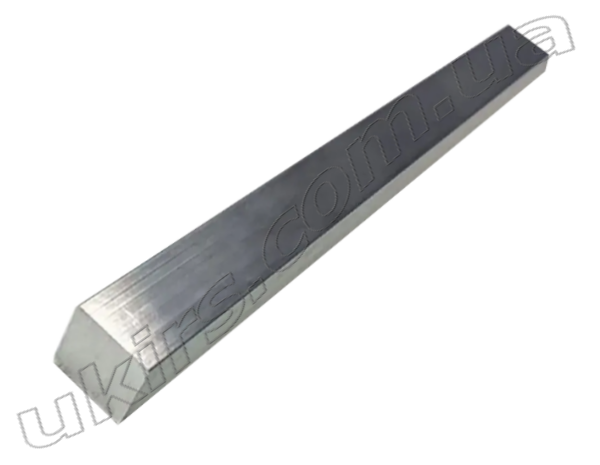

Hexagon

Stainless steel hexagon is a stainless steel product that has a hexagonal shape in cross section. Hexagonal rods have a wide range of applications.

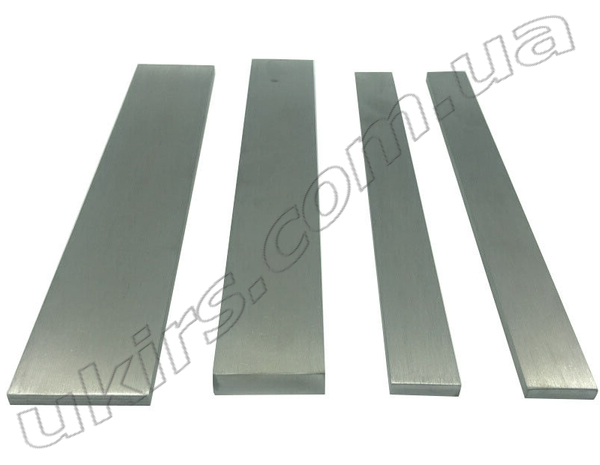

Stripe

Stainless strip is a type of stainless rolled metal product. It has the form of a solid rectangular section. It has the following dimensional characteristics: width, thickness and length.

Wire

Stainless wire is a long product made of stainless metal. It is usually made in the form of a cord or thread and supplied in coils or special reels.

Shaped - angle, channel, I-beam, rail, profile (type П).Corner

Stainless steel angle is a product with two shelves located at a right angle. It is divided into equal-shelf and unequal-shelf. According to the manufacturing method, it is divided into hot-rolled (forged) - has a clear outer angle, and bent (cold bending) - the outer angle has a slight rounding.

Profile type П-shaped

Stainless steel profile type П-shaped - a product made of stainless metal, obtained by rolling, pressing, forming (bending) between rollers. П-shaped profiles are divided into: a profile with a constant and / or variable cross-section along the length (including periodic).

tubular

Stainless steel profile pipe with the following cross-sectional shapes: square, rectangular, triangular, oval, flat-oval. Manufactured using a technological line of welding machines by welding a round blank with its simultaneous profiling.Square

Square stainless steel pipe - standard profile pipe with a cross-section in the form of a square (equilateral rectangle). It is used quite widely from production to decoration, etc.

Rectangular

Rectangular stainless steel pipe has a rectangular shape in cross-section. It is actively used in the production of various types of structures. It is in great demand.

Oval (flat-oval)

Flat oval stainless steel tube: two sides are always flat, two are rounded and have a semi-oval shape. Mainly used for making furniture fittings and decorative purposes.

Triangular

Triangular stainless steel pipe - a type of profile pipe with a cross-section in the shape of a triangle (equilateral or unequal). This is an unusual type of profile pipe: due to the absence of one side, it has less weight and cost accordingly.

Elliptical (elliptical)

Elliptic stainless steel pipe (elliptical) - has a cross-sectional shape in the form of an ellipse. It is usually produced by welding from a round blank with subsequent finishing on special equipment to the desired elliptical shape. It is in great demand among railing manufacturers.

With a groove

Stainless steel pipe with a special groove. The groove can be either on one side of the pipe or on several sides at the same time. The groove can be square or rectangular (deep) in section. The outer shape can also be of different shapes: square, rectangular, round, etc.

Type L

Stainless steel profile pipe type L is a type of stainless steel rolled metal pipe which in cross-section resembles the Latin letter L or stainless steel angle. Such a pipe has an angle of 90°. It is divided into equal-flange and unequal-flange.

Stainless steel round pipe.Round

Stainless steel round pipe - this is a type of stainless steel tubular rolled products of round cross-section. It is made from sheet metal by welding (welded, seam pipe with a seam inside) or by hot deformation (seamless, solid-drawn stainless steel pipe without a weld inside).

Stainless steel pipe of variable cross-section comes in several types. For example: conical, corrugated, decorative. Each has its own purpose and is distinguished by a changing cross-section shape.Decorative

Decorative stainless steel pipe has the highest cost due to the additional cost of its manufacture. It is usually produced using a machine set and a mold. It is used for structural purposes ranging from aesthetic to highly functional.

Corrugated

There are two types of corrugated stainless steel pipe: standard unannealed and soft annealed. Annealed is passed through a special furnace, where it is annealed and this gives it greater flexibility and plasticity. The cost of soft is higher than standard corrugation, due to additional heat treatment.

Cone-shaped

Conical stainless steel pipe is produced by welding. It differs from the usual round pipe by its non-constant diameter along its length. It is usually used for further production of adapters. There are two types: concentric and eccentric.

Separately, we will highlight the stainless perforated pipe. According to the cross-sectional shape, it can be either round or profile with its subtypes.Perforated

Perforated stainless steel pipe is a type of rolled pipe characterized by the presence of a certain number of holes in its plane. The holes can be of any shape and size.

As you can see from the above, stainless rolled metal differs from other widely used metals by its simply incredibly fantastic and huge variety of different forms. It is this variety that enables designers and engineers to transform this unusually beautiful and practical material into original products, super-strong structures, pipelines and many other useful things.Classification by manufacturing method

The production of one or another type of stainless rolled metal is a process of changing the size of metal shapes under the action of applied forces. This process can also be called "deformation". According to the temperature of the manufacturing process, rolled metal is divided into:hot rolled

Hot deformation - deformation of a crystalline material at the recrystallization temperature or slightly higher.Recrystallization is the process of formation and growth (or just growth) of some crystalline grains (crystallites) of a polycrystal at the expense of others. The rate of recrystallization increases sharply (exponentially) with increasing temperature.Hot deformation of stainless rolled metal is characterized by such a ratio of deformation and recrystallization rates, at which recrystallization has time to occur in the entire volume of the workpiece. The crystalline structure of the material after pressure treatment turns out to be practically equiaxed and without any signs of hardening.casting

- is a process of manufacturing a workpiece or product from a liquid material by filling it into a cavity of specified shapes and sizes with subsequent hardening. In the most common understanding - a typical process-operation for obtaining products, consisting of filling a special container (mold) that forms the surface or part of the surface of the manufactured product, with molten stainless metal with subsequent thermal-temporal transition of the liquid material into a solid aggregate state and obtaining, as a result, a solid workpiece, close in configuration, size and properties to the product.cold rolled

Cold deformation is a metal processing by pressure, carried out at room temperature or slightly different from it. This method is characterized by a change in the shape of a single grain. The grains are stretched in the direction of the flow of the stainless metal, forming a line microstructure. During cold deformation, the change in shape is accompanied by a change in the mechanical and physical-mechanical properties of the metal; as the degree of deformation increases, the strength characteristics increase, and the plasticity characteristics, on the contrary, decrease.welding

This is the process of obtaining permanent connections by establishing interatomic bonds between the parts being welded during their local or general heating, plastic deformation, or the combined action of both. There are about 200 types and methods of welding processes. There are various methods of classifying these processes.Classification by type of surface treatment

Modern technologies, means and methods of processing the surface of stainless rolled metal products allow to obtain hundreds, if not thousands, of different types of surfaces. We will try to classify them (to organize them in a certain way), since when choosing a type of surface, customers very often have additional questions about it.There are five main types:⓵ unprocessed

⓶ polished (satin)

Grinding (grinding) is an operation for processing the surface of stainless rolled metal using abrasive materials. This process can be of two types: mechanical or manual.⓷ mirror (polished, gloss)

⓸ matte

⓹ decorative