Stray current corrosion of stainless steel (electrocorrosion) is a type of corrosion that occurs in the presence of stray current. Stray current is current that flows in paths other than those provided by the circuit. The uniqueness of stray current corrosion of stainless steel is that it can only occur at the discharge point.

Stray current corrosion is a dynamic and transient type of corrosion. It is electrically related and can be caused even by traditional corrosion prevention methods. Although it therefore seems inevitable, its catastrophic results cannot be tolerated or ignored.

This corrosion can be rapid if the current generated by the galvanic cells is less than the stray current. When the current leaves the metal and flows into the electrolytic medium, the part from which the current leaves is subject to severe corrosion. Some grades of stainless steel can be destroyed quite quickly.

Stray currents can be both external and internal, with internal ones causing short circuits in electrical wiring.

Very often "stray currents" are called "zero currents" that exist in metal ungrounded (not zeroed) structures. The incorrect use of the term does not reduce the destructive capabilities of such electric currents.

Stray current corrosion of stainless steel: characteristics

Stainless steel, although resistant to corrosion in many environments, can be subject to corrosion by stray currents.

There are two main types of stainless steel corrosion caused by stray currents:

- Localized galvanic corrosion: this type of corrosion occurs where a stray current passes from the stainless steel to another, more electronegative metal, such as steel or cast iron. At these locations, the stainless steel quickly dissolves.

- Subsurface corrosion: this type of corrosion occurs when stray current passes through the soil. Chlorine ions and other aggressive substances in the soil can accelerate corrosion.

When stainless steel comes into contact with stray currents, it can become an anode, causing it to dissolve electrochemically. This phenomenon is known as stray current corrosion.

- This is not natural corrosion because it can be caused by an external and independent factor that is not dependent on the environment.

- The potential difference with a less leading environment arises when a stray current passes through, creating a corrosion cell.

- This may affect the service life and safety of pipelines and other metal structures.

- In fact, it is electrochemical corrosion.

- The main factors that contribute to the formation of corrosion from stray currents include high electrical resistance, poor installation of metals in the ground, and voltage drops caused by too great a distance between substations.

Stray current corrosion is a relatively common form of stainless steel corrosion that can be devastating if not addressed promptly in stainless steel structures - especially in piping.

Detection of stainless steel corrosion from stray currents

Identifying this particular type of corrosion requires some skill and experience. Other types of corrosion are commonly misdiagnosed as stray current corrosion by unqualified corrosion consultants. This stray current corrosion is determined by visual inspection by a certified corrosion consultant. Stray current corrosion looks different from other types/kinds of non-stray current corrosion due to the process of electrolysis. Environmental factors are not a factor, although they usually play a significant role in other types of stainless steel corrosion.

Any buried metal structure is subject to stray current corrosion. It most commonly affects railroads, pipelines, storage tanks, and other large structures made of stainless steel.

Stray current corrosion is often confused with galvanic corrosion. It differs significantly from galvanic corrosion in that it is corrosion between two dissimilar metals, while stray currents are not subject to environmental corrosion and can cause much greater damage.

Signs of corrosion of stainless steel by stray currents:

- Rusty spots or pits on the surface of stainless steel.

- Thinning of the walls of pipes or other stainless steel structures.

- Cracks in stainless steel structures.

- "Perforation" of stainless steel.

Causes of stainless steel corrosion from stray currents

Stray current corrosion, as mentioned earlier, is a unique form of corrosion. It is not caused by environmental factors. It occurs when current flows in a different path than intended.

Stray current is when electricity flows abnormally. This can happen in many situations. One of the most common causes of stray current is improper installation or lack of maintenance of the electrical system. There are many things that can cause electrical current to stray from its intended path. Sources of stray current include:

- Corrosion prevention systems with cathodic protection.

- Direct currents that distribute energy are grounded.

- Electric-powered rapid transit systems.

- Electric welding equipment.

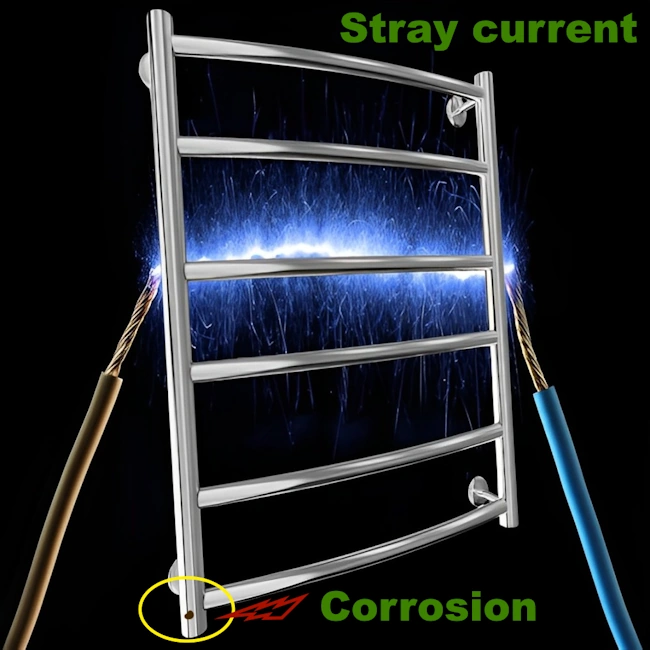

How can these stray currents be formed? Imagine a stainless steel heated towel rail connected to metal-plastic/plastic pipes. When moving, the water is electrified due to friction against the walls (dielectric), and the static charge accumulates on the metal elements, creating a kind of capacitor (if the pipes were conductive metal, the charge would not accumulate). What happens next is that this capacitor is discharged, a small current flows, and one of the metals begins to deteriorate, just like in electrochemical corrosion.

The problem of corrosion of stainless steel faucets and heated towel rails is precisely that plastic pipes are connected to them. The riser, of course, is made of metal pipes. All metal pipes are grounded, in new houses through the potential equalization system, in old houses - in the basement to the ground loop. When using plastic pipes, the metal connection between the riser pipes and the stainless steel heated towel rail is broken. Consequently, the potential is broken: on the riser you have one - the ground, on the faucet (heated towel rail) - another. This phenomenon is called - potential difference. An electric current appears between different potentials when a conductor appears between them. Such a conductor is water. When water moves through the pipes, microfriction of different media occurs: water and metal, and friction generates voltage. That is, the potential that is equal to the earth potential in the riser (grounded), and the one in the heated towel rail is on its own, and through the water between different potentials, "stray currents" arise, and, as a result, corrosion.

Methods and ways to prevent corrosion of stainless steel from stray currents

Let's start with the fact that if all elements of the pipeline are installed correctly, there should be no stray currents. Correct installation means grounding all metal elements (heating radiator, heated towel rail, sink, bathtub, faucets).

How to avoid: ground all metal elements of the system. Especially when using plastic pipes.

Water has excellent conductivity. All you need to do is to provide a reliable metal connection between the riser pipes and the metal end devices (mixer, heated towel rails). Simply put - ground your heated towel rail to the metal riser pipes and all wandering troubles will leave you immediately, the potential will equalize and the current will have nowhere to flow from.

Cathodic protection is often insufficient to prevent stray current corrosion on at-risk stainless steel structures. Investment in stray current mapping is essential for prevention.

Stray current mapping is a safe way to map out the path of stray current. Knowing the path of stray currents and having a regularly monitored reliable cathodic protection system will help prevent problems associated with the formation of corrosion cells due to stray currents.

Cathodic protection can cause stray currents, which can lead to corrosion. Cathodic protection is designed to protect structures from corrosion, but it can actually cause stray current corrosion. For best results, it should be monitored and assessed by certified corrosion consultants.

Corrosion of stainless steel from leakage currents

Leakage current is not stray current, it's different. For some reason, current flows through a stainless steel pipe, and the steel is destroyed, just like in galvanic corrosion.

Corrosion of stainless steel from leakage currents can lead to serious problems such as:

- Equipment damage: corrosion can cause stainless steel components to deteriorate, which can lead to equipment failure and costly repairs.

- Reduced strength: corrosion can weaken stainless steel, which can make it more prone to cracking and breaking.

- Leakage: in some cases, corrosion can cause liquid or gas to leak from the equipment, which can be hazardous to people and the environment.

If installed correctly, there should be no current flowing through the pipes. However, current can flow through the pipes if someone has connected the grounding of an electrical appliance to the riser. This is dangerous primarily not because of corrosion, but because of the danger to life. Imagine that the riser was disconnected during repairs and there is no grounding. Current can flow through the pipes due to faults in the grounding, zeroing, and potential equalization systems.

How to avoid:

- Do not use water pipes or heating pipes as grounding for electrical appliances.

- Correctly install the grounding, zeroing and potential equalization system.

- Use differential circuit breakers that respond to leakage currents of up to 30 milliamps.

Stray current corrosion is comparable to galvanic corrosion, where the current is generated internally, although other measures may be taken to eliminate it. The chemical and electrical reactions at the interface between the electrolyte and the metal are also similar. The corroding metal is considered the anode, with the current flowing to the cathode.

If you suspect that stainless steel is subject to stray current corrosion, it is recommended that you contact a corrosion specialist to diagnose and develop a plan to protect your structure, product, or equipment.