Parking / anti-parking or sidewalk bollard (street bollard) made of stainless steel is a metal product made of stainless metal, related to the type of parking equipment. Purpose: for fencing territories, delimiting automobile / transport and pedestrian zones, serves to organize parking or prevents parking in prohibited areas. Can be used both outside and inside buildings and in underground parking lots to separate individual zones.

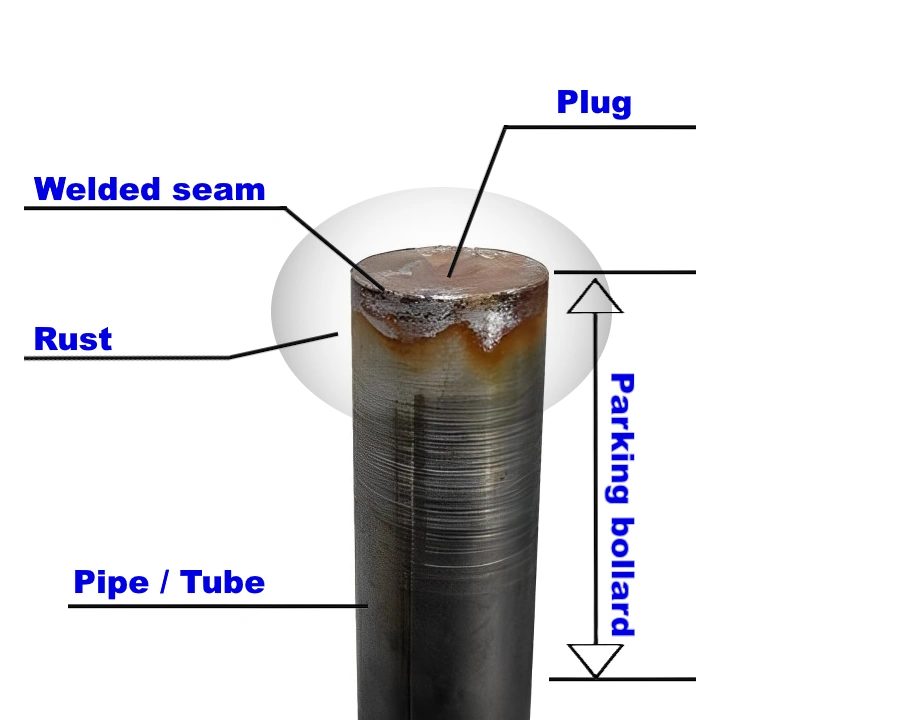

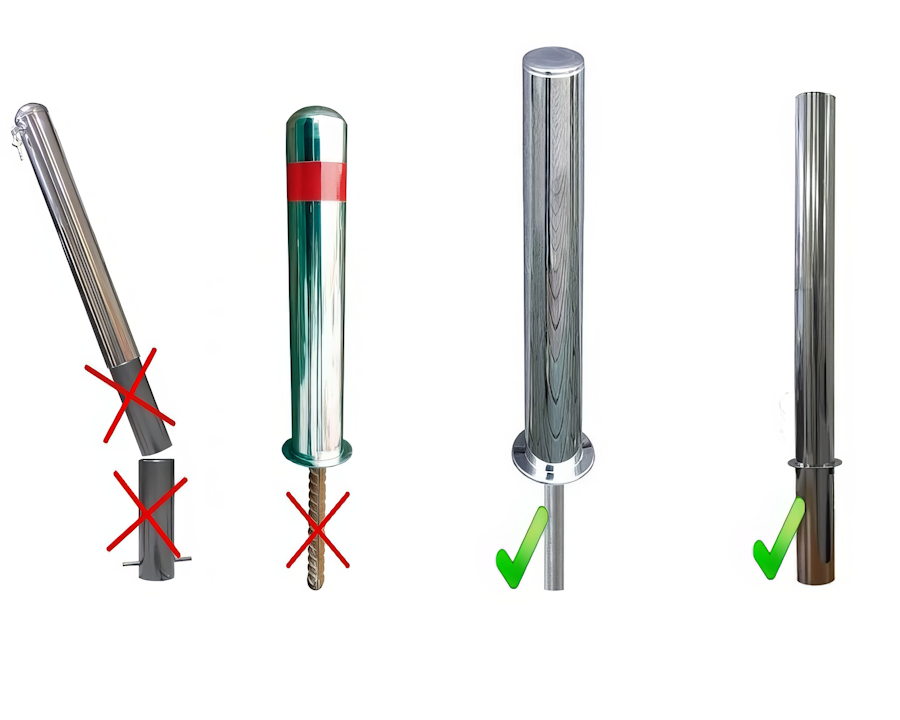

Most often, such products are made from a round stainless steel pipe of a certain diameter, less often, from a square or rectangular stainless steel profile pipe of a cross-section. Very rarely, sidewalk bollards that are truly reliable and ensure pedestrian safety are made from a stainless steel round bar (stainless steel circle).

When using such products, a frequent and serious problem is rusting, which appears on the front surface of the metal of the post. Rust spoils the appearance of the entire structure and, over time, can lead to partial or complete failure of such equipment.

Why does it rust ?

Often, in pursuit of super profits, manufacturers use the cheapest grades of stainless steel to make posts, which, due to their properties, simply cannot resist certain types of corrosion.

To explain the cause of rust from a scientific/technical point of view, you first need to take a specific pole that has rusted and, as they say, turn it inside out. Conduct all available and necessary examinations and compare the obtained indicators with the indicators and technical characteristics specified by the manufacturer. If the customer of the poles has the opportunity (and the control body or a particularly large budget / state customer definitely has such an opportunity), the main thing is to establish by full spectral analysis the chemical composition of the metal that has rusted and the grade of stainless steel from which this product is made. Also, if the pole is made of a pipe, establish the thickness of the pipe wall and compare it with the specified thickness specified by the manufacturer in the contract or in another document (the wall thickness does not affect the corrosion processes, and establishing its actual thickness is a check of the manufacturer / supplier for integrity). Be sure to find out what is contained in the middle of the parking/sidewalk pole if it is made of a pipe. Check the quality of the welds, if any. If there are discrepancies, those responsible must be punished, because sometimes the amount of damage caused can reach tens and even hundreds of millions of dollars.

Also find out whether this is a single case or a systemic one (if there are many columns installed). Find out which part of the column is covered with rust: the bottom, the top where the plug is welded to the pipe, or all parts are covered with rust.

Once all the technical characteristics and chemical composition of the column material have been established, the first conclusions regarding the appearance of rust can be made.

But first, a quick word about rust and corrosion of stainless steel:

Corrosion

Corrosion is the gravity-driven destruction of metal and alloys, as well as other substances, as a result of chemical, electrochemical or physicochemical interaction with the environment. The main types of corrosion by their mechanism include chemical, electrochemical and biological.

Rust

Rust is a product of corrosion or its result. Simply put, it is the formation that we see with the naked eye on the surface of the product.

What are the causes of corrosion and rust on the surface of a stainless steel post ?

⓵ In the manufacture of the post, the manufacturer used a cheap grade of low-quality stainless steel. Such steel, due to its weak anti-corrosion properties, is simply not capable of resisting the corrosion processes caused by the action of the environment in which the post is used.

⓶ If the column structure is based on a stainless steel pipe, and rust has appeared on the welded seams (for example, in the upper part of the column at the junction / weld of the plug to the pipe), the most likely cause of rust in such a place is the manufacturer's violation of the stainless steel welding technology and improper processing of the welded seams.

This type of corrosion is called intercrystalline corrosion. Some stainless steel grades become sensitive to this type of corrosion during welding, when the temperature rises to 500 - 900 °C and carbides are deposited in the intercrystalline space, which leads to a decrease in chromium (burning of chromium) at the weld site. During welding, the protective oxide film on the stainless metal is destroyed - corrosion deformation of the weld. The corrosion resistance of the welds decreases as a result if the manufacturer has not taken measures to fully restore their corrosion resistance (for example, passivation of the weld site was not carried out).

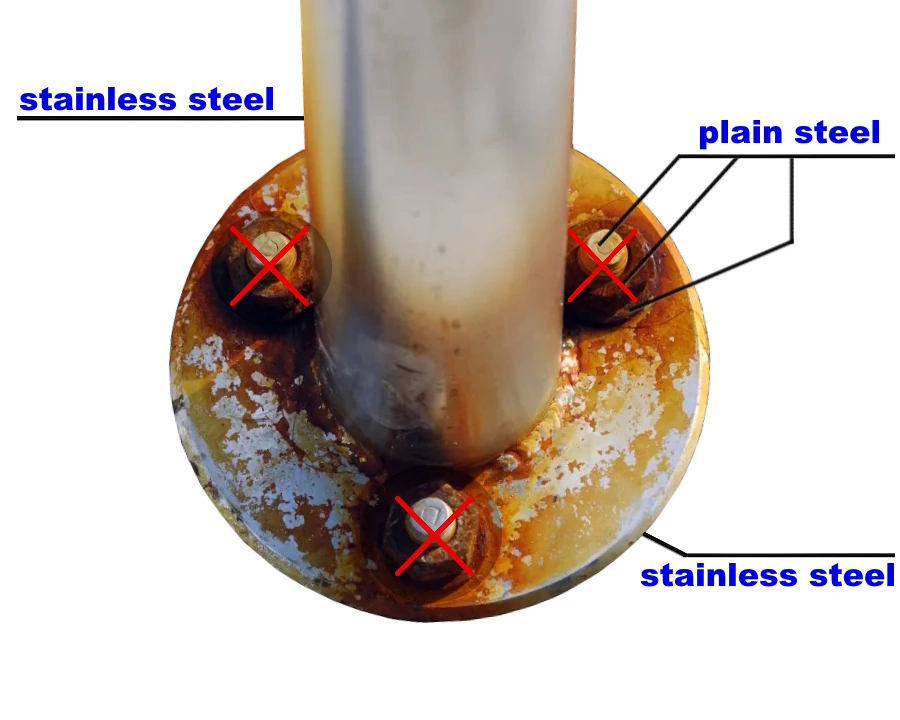

⓷ Contact corrosion. This type of corrosion occurs when different metals come into contact, for example stainless steel + regular steel. The more noble metal causes corrosion (rusting). The so-called contact corrosion occurs. The condition for this process is the presence of a corrosive environment between the two metals, for example water or humid air.

If the post mount is made of regular or galvanized metal, rust is inevitable. The rate at which it appears depends on the level of humidity in the environment.

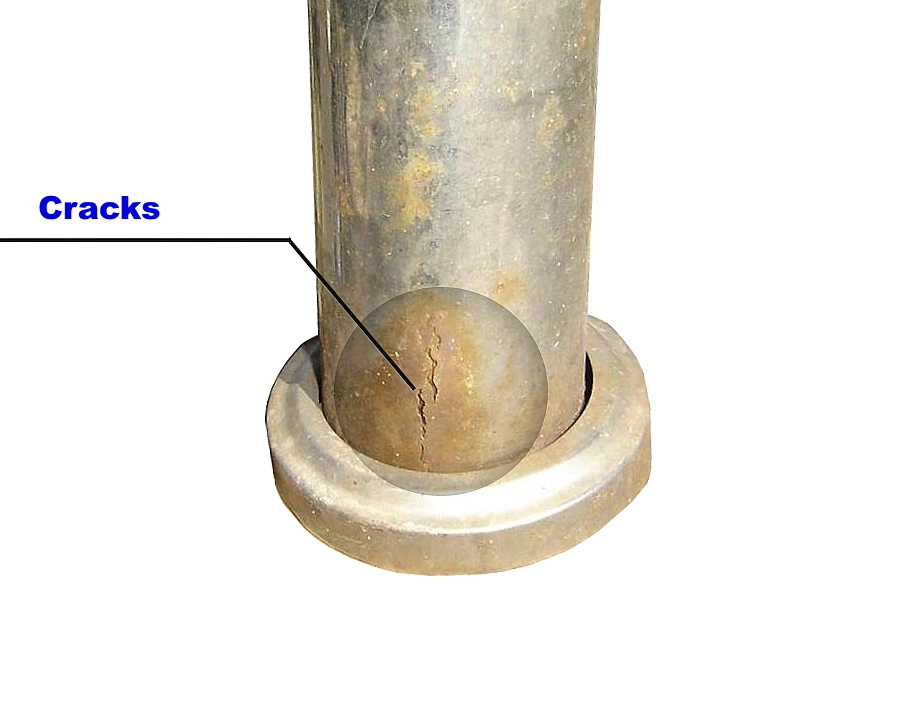

Contact corrosion can be combined with crevice corrosion. Crevice corrosion of stainless steel is an increased destruction in gaps, crevices, cracks, manifested in conditions of close location of two surfaces. It is one of the types of local electrochemical corrosion.

As for the concrete reinforced posts:

- concrete contains chemicals that cause corrosion. Concrete splashes on the surface of stainless steel should be removed immediately, and the surface should be properly washed and cleaned. If this is not done in time, the consequences may be unpleasant;

- concrete is a material that retains moisture well and is an excellent conductor of it. Thus, in the middle of a column reinforced with concrete, especially in the soil part of the column, ideal conditions for the development of corrosion processes are created: constant moisture, no access to oxygen, black reinforcement, concrete. The protective film on the surface of the stainless steel column does not hold up and begins to break down. In the best case, the concrete inside the column should be waterproofed;

- concrete and stainless steel have different coefficients of thermal expansion. What does this mean? On a sunny hot day outside, the metal heats up and expands more than the concrete inside the column, and at night, when the temperature drops, the reverse process of contraction occurs. Thus, firstly, there will always be a gap (crack) between the column and the concrete, which can cause so-called crevice corrosion when moisture gets into it. And secondly, when the stainless steel of a column filled with concrete contracts, constant pressure occurs in the middle. Eventually, the strength of the concrete decreases and it begins to collapse (crack, crumble) along with the waterproofing layer. The pipe itself also collapses under pressure. Microcracks begin to appear in its wall and in the welds, which will also inevitably lead to corrosion processes.

⓸ General / partial (partial most often in the near-soil zone) corrosion on posts can occur under the influence of salts, chemicals, reagents used on the streets for snow melting in the autumn-winter period. And if the grade of stainless steel from which the post is made has weak anti-corrosion properties and is not designed for such operating conditions, the protective layer is destroyed and this leads to rusting.

⓹ Atmospheric corrosion. Can be both general and local. Most often, it appears on stainless steel posts in marine or coastal areas.

The reason for the appearance of rust is the incorrect selection of the grade of stainless steel for the operating conditions and atmospheric corrosion factors: air humidity, impurities (gases) and solid particles in the atmosphere, cathode inclusions, geographic factors and ambient temperature.

Conclusion

When purchasing such equipment as a sidewalk, parking / anti-parking bollard made of stainless steel - choose only reliable, time-tested manufacturers and suppliers. If possible, look at their products and evaluate their appearance and quality in real street conditions, in which the bollards have already been in operation for at least several years. You can also contact sellers / suppliers of stainless steel rolled metal - they will definitely be able to suggest a conscientious manufacturer, because who better than they knows which manufacturers buy only high-quality materials for bollards.