Stainless steel and rolled metal standards

Standards

Stainless steel and rolled metal standards (quality standards, conformity standards) - are national and/or international documents containing requirements, specifications, recommendations or characteristics that can be used to ensure that materials, products, processes and services are suitable for their intended purpose.

Standards provide organizations with the common vision, understanding, procedures, and vocabulary needed to meet stakeholder expectations. Because standards provide precise descriptions and terminology, they offer organizations and consumers around the world an objective and authoritative basis for communicating and doing business.

ASTM A554 | Tolerances: diameter, wall thickness, out-of-roundness

ASTM A554

- is an internationally recognized standard of the American Society for

...Chemical compatibility and resistance of stainless steel

The chemical compatibility and resistance of stainless steel depends on the specific type, grade of steel and the environment with which it comes into contact. There are many different

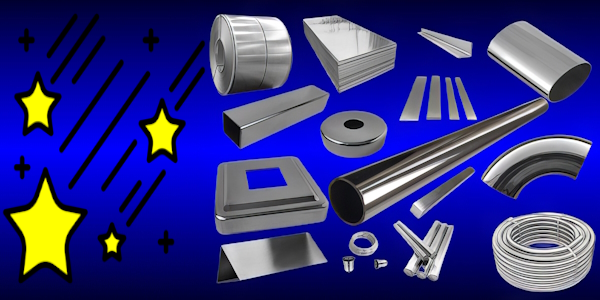

...Classification of stainless rolled metal products

Stainless rolled products in metallurgy (stainless rolled metal products) - products made of stainless steel, obtained on rolling mills by hot, warm or cold

...Compatibility of stainless steel with other metals | Galvanic couple

The compatibility of stainless steel with other metals depends on the specific type/grade of stainless steel and the metal it comes into contact with. Stainless steel is compatible with

...EN 10357 standard | DIN 11850

EN 10357 | DIN 11850 - is a European standard defining the dimensions, tolerances and manufacturing conditions for stainless steel pipes and fittings used in the chemical, food

...Manufacturing equipment for the food industry: why is the choice of stainless steel a matter of safety?

The choice of materials in the food, pharmaceutical, and chemical industries is not just a technical requirement, but a critically important decision that affects the quality,

...Maximum allowable working pressure for stainless steel round welded pipes

Stainless steel welded tubes manufactured in accordance with EN 10357 (DIN 11850) and EN 10217-7 (DIN 17457) can be used for pressure applications at room, low and elevated

...Maximum temperature for some heat-resistant stainless steel grades for use in air

The maximum temperature of stainless steel in air depends on the type of stainless steel and the operating conditions. In general, stainless steels can be used in air at temperatures up

...