Stainless steel welding | Stainless steel processing

Welding | Processing

Welding and processing of stainless steel - are some of the most important and responsible processes when working with corrosion-resistant metals and alloys that contain chromium and other alloying elements. There are more than a hundred unique grades of stainless steel and corrosion-resistant alloys. They differ in internal structure, chemical composition, physical and mechanical properties, degree of corrosion resistance, etc. Such diversity requires certain experience and knowledge when welding and processing a specific grade or type of stainless steel.

Bending stainless steel pipe

Stainless steel pipe bending is a manual, automatic / mechanical or combined process of metal forming to obtain the desired shape using stainless steel pipe bending equipment,

...Electrical discharge machining of stainless steel

Electrical discharge machining of stainless steel is a type of electrophysical metal processing. It is characterized by the fact that the change in shape, size and surface quality

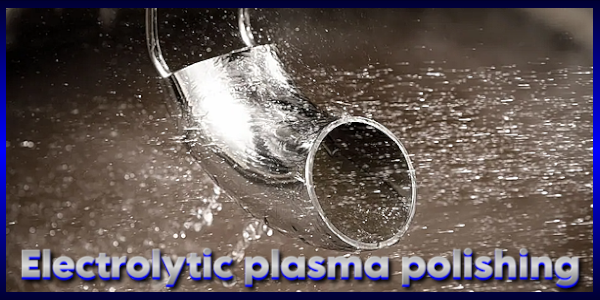

...Electrolytic plasma polishing of stainless steel | Electroplasma polishing

Electrolytic-plasma polishing of stainless steel (electroplasma polishing) is a process of treating the surface of stainless steel based on physical phenomena occurring on the

...Laser welding of stainless steel

Laser welding of stainless steel is a fusion joining process that fuses materials using heat generated from a concentrated beam of coherent monochromatic light incident on the

...Stainless steel weld treatment | Passivation

Processing of stainless steel weld seam is one of the most important stages of the process of manufacturing a high-quality product, part, construction from stainless steel.

...The best ways to cut stainless steel pipes / tubes

Stainless steel is a versatile alloy widely used in various industries including aerospace, construction, automotive, pharmaceutical, etc. Stainless steel tubes are commonly used in

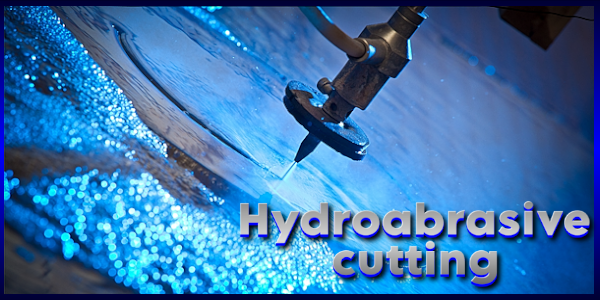

...Waterjet cutting of stainless steel

Waterjet cutting of stainless steel is a type of technological process for processing stainless metal, in which the cutting tool, instead of cutters, is water enriched with

...Welding stainless steel

Welding stainless steel is a process of obtaining permanent joints by establishing interatomic bonds between the welded parts of stainless metal during their local or general

...