Elmax Stainless Steel | Uddeholm Elmax SuperClean is a high-quality stainless steel produced by the Uddeholm Group using powder metallurgy. It holds an edge well, is difficult to sharpen, and is quite strong. It is a very fine-grained steel, so it allows for very aggressive sharpening. It allows for hardening the material to 62 HRC while maintaining decent strength. Due to its high chromium content, it has high corrosion resistance.

ELMAX steel (stainless steel ELMAX) is a high-tech steel that is classified as a third-generation steel. It is one of the newest powder materials, and for quite a long time remains almost the optimal choice in terms of price / quality in the production of knives.

Elmax (Elmah steel) is stronger than S30V and has better edge holding than S35VN. It is produced using third generation stainless steel powder metallurgy. The grain size of the metal powder is very small.

Characteristics

Uddeholm Elmax SuperClean is a chromium-vanadium-molybdenum alloy steel with the following characteristics:

- High wear resistance

- High compressive strength

- Corrosion resistance

- Very good dimensional stability

High wear resistance is usually associated with low corrosion resistance and vice versa. However, Uddeholm Elmax SuperClean has achieved this unique combination of properties through powder metallurgy-based manufacturing. Uddeholm Elmax SuperClean offers the ability to produce durable, maintenance-free moulds for better overall moulding economy.

Chemical composition

Chemical composition of Elmax steel grade | ||||||||

| C | Cr | Mo | W | V | Mn | Si | Ni | Fe |

| 1,7 | 18 | 1,0 | 0,11 | 3,0 | 0,35 | 0,8 | 0,15 | Other |

Heat treatment

Soft annealing

Protect the steel and heat to 980 °C, holding time 2 hours. Then cool in the furnace at a rate of 20 °C/h to 850 °C. Holding time 10 hours. Slowly cool to 750 °C. Then freely in air.

Stress relieving

After rough machining, heat the workpiece to 650 °C, hold for 2 hours. Cool slowly to 500 °C, then freely in air.

Hardening

- Preheating temperature: 600 - 850 °C.

- Austenitization temperature: 1050 - 1100 °C, typically 1080 °C.

| Temperature °C | *Holding time in minutes | Hardness before tempering (HRC) |

| 1050 | 30 | 60 |

| 1020 | 30 | 61 |

*Holding time = time at austenitizing temperature after the tool is fully heated through.

Protect the part against decarburization and oxidation during hardening.

Tempering

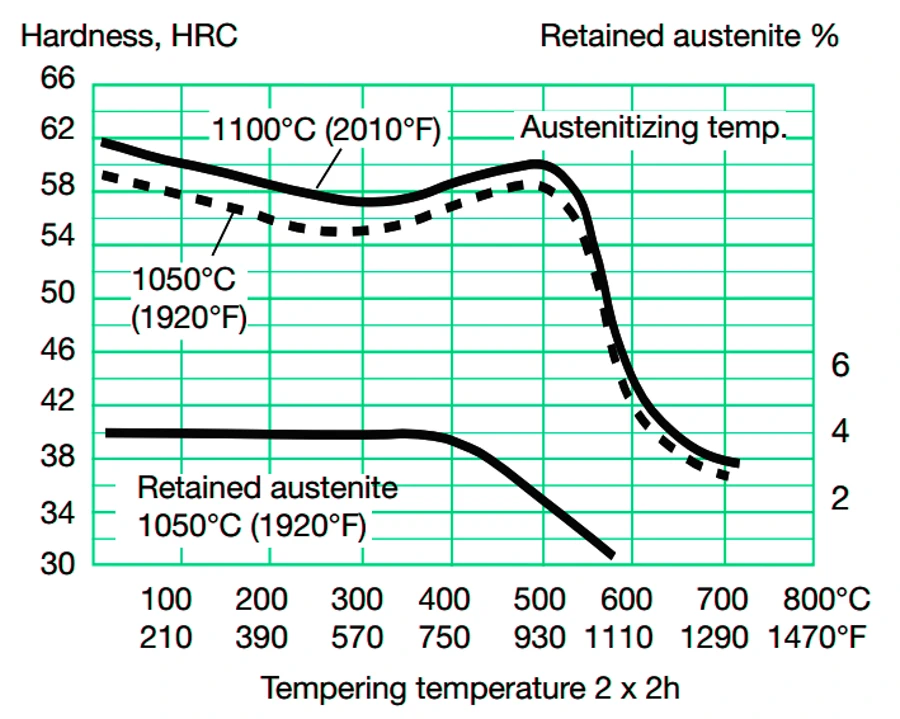

Choose the tempering temperature according to the hardness required by reference to the tempering graph. Temper twice with intermediate cooling to room temperature, the preferred tempering temperature is 250 °C or higher. In exceptional cases, a minimum tempering temperature of 180 °C can be used for small simple inserts and parts where toughness is of less importance. Holding time at tempering temperature minimum 2 hours.

Above tempering curves are obtained after heat treatment of samples with a size of 15x15x40 mm, cooling in forced air. Lower hardness can be expected after heat treatment of tools and dies due to factors like actual tool size and heat treatment parameters.

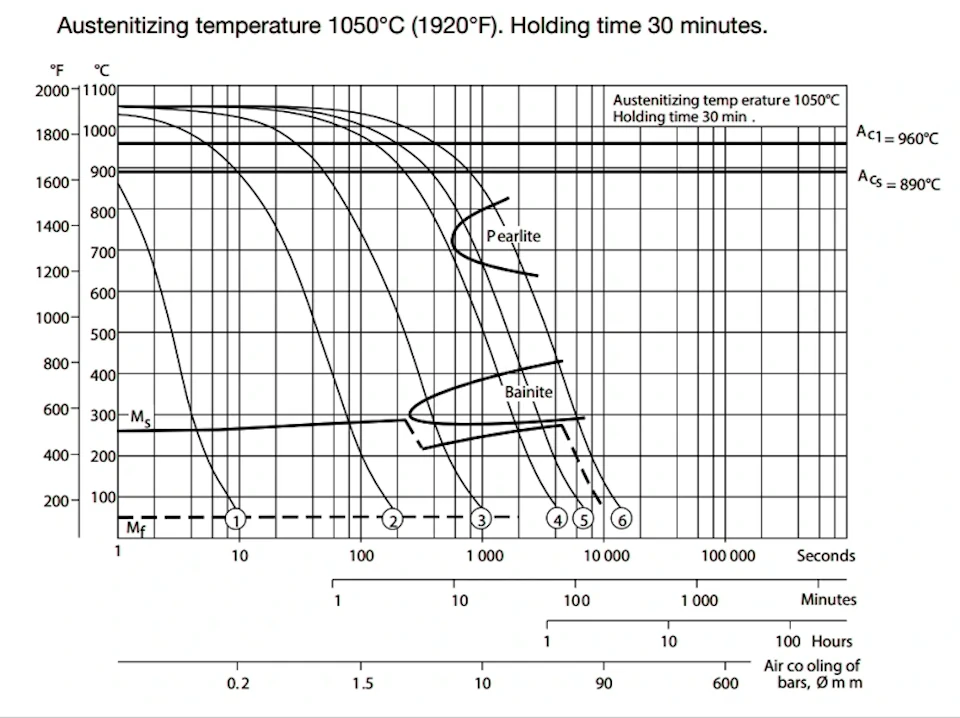

Phase diagram of continuous cooling ( CCT )

Austenitizing temperature 1050 °C (1920 °F). Holding time 30 minutes.

| Cooling curve no | Hardness HV10 | Т 800-500 (sec) |

| 1 | 792 | 1 |

| 2 | 782 | 28 |

| 3 | 690 | 140 |

| 4 | 665 | 630 |

| 5 | 542 | 1030 |

| 6 | 360 | 2095 |

Quenching environment

- Forced air / gas.

- Fluidized bed or salt bath 200 - 550 °C (390 - 1020 °F), then cool in air

Note. Note: In order to obtain optimum properties, the cooling rate should be as fast as is concomitant with acceptable distortion. Temper immediately the tool reaches 50 - 70 °C (120 - 160 °F).

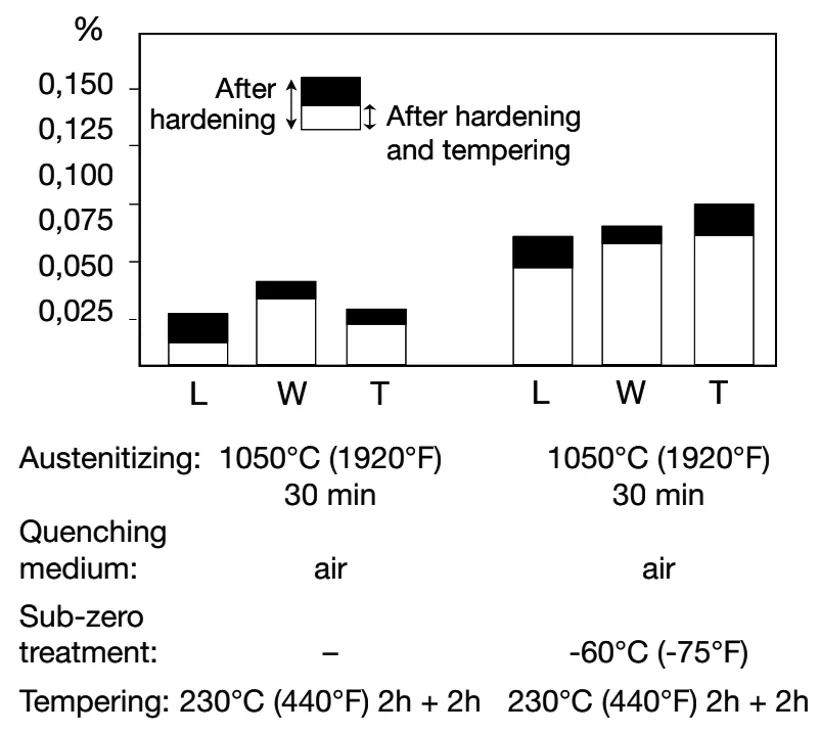

Changes in size during heat treatment

Illustration of the effect from austenitizing temperature and subzero cooling. The test has been performed on sample size: 40x40x40 mm (1,6x1,6x1,6 in.).

Processing at sub-zero temperatures

Sub-zero treatment falls into the broad categories of cold treatment and cryogenic treatment.

Parts requiring high dimensional stability should be sub-zero treated, otherwise volume changes may arise.

Uddeholm Elmax SuperClean is commonly sub-zero treated between -150 °C (-240 °F) and -196 °C (320 °F) (cryo treatment), although occasionally -40 °C (-40 °F) to -80 °C (-112 °F) (cold treatment) are used due to constraints of the sub-zero medium and equipment available.

The first sub-zero treatment should be carried out directly after hardening and before any tempering without delay. When maximum dimensional stability is required further sub-zero treatments may be necessary between the tempering operations. In this case it is important to always end with a tempering, as the last operation.

1 - 3 hours treatment results in an increased hardness of about 1 - 3 HRC.

Note. Avoid intricate shapes as there is a risk of cracking.

Mechanical processing: recommendations

The machining recommendations below are to be considered as guiding values which must be adapted to existing local conditions.

Turning

| Cutting data parameters | Turning with carbide | High speed steel | ||

| Rough turning | Fine turning | Fine turning | ||

| Cutting speed (vc) m/min. | 70 - 120 | 120 - 140 | 10 - 14 | |

| Feed (f) mm/r. | 0,2 - 0,4 | 0,05 - 0,2 | 0,05 - 0,2 | |

| Depth of cut (ap) mm | 2 - 4 | 0,5 - 2 | 0,5 - 3 | |

| Carbide designation | ISO | K20, P10 - P20 | K15, P10 | - |

| US | C2, C7- C6 | C2, C7 | - | |

| *Coated carbide | *Coated carbide | - | ||

* Use a wear resistant Al2O3 coated carbide grade

Drilling

High speed steel twist drills

| Drill diameter mm | Cutting speed (vc) m/min | Feed (f) mm/r |

| до - 5 | 10 - 12* | 0,05 - 0,15 |

| 5 - 10 | 10 - 12* | 0,15 - 0,20 |

| 10 - 15 | 10 - 12* | 0,20 - 0,25 |

| 15 - 20 | 10 - 12* | 0,25 - 0,35 |

* For coated HSS drills vc = 18 - 20 m/min.

Carbide drills

| Cutting data parameters | Type of drill | ||

| Indexable insert | Solid Carbide | Carbide tip1) | |

| Cutting speed (vc) m/min. | 90 - 120 | 60 - 80 | 30 - 35 |

| Feed (f) mm/r. | 0,05 - 0,252) | 0,10 - 0,253) | 0,15 - 0,254) |

- 1) Drill with replaceable or brazed carbide tip.

- 2) Feed rate for drill diameter 20 - 40 mm.

- 3) Feed rate for drill diameter 5 - 20 mm.

- 4) Feed rate for drill diameter 10 - 20 mm.

Milling

Face and square shoulder milling

| Milling with carbide Cutting data parameters | Rough milling | Fine milling |

| Cutting speed (vc) m/min. | 80 - 110 | 110 - 140 |

| Feed (fz) mm/tooth | 0,2 - 0,4 | 0,1 - 0,2 |

| Depth of cut (ap) mm | 2 - 4 | до - 2 |

| Carbide designation ISO | K20, P20 | K15, P10 |

| Carbide designation US | C2, C6 | C2, C7 |

| - | Coated* carbide | Coated* carbide |

* Use a wear resistant Al2O3 coated carbide grade

End milling

| Cutting data parameters | Type of end mill | ||

| Solid carbide | Carbide indexable insert | High speed steel | |

| Cutting speed (vc) m/min. | 50 - 60 | 80 - 110 | 5 - 81) |

| Feed (fz), mm/tooth | 0,01 - 0,202) | 0,06 - 0,202) | 0,01 - 0,302) |

| Carbide designation ISO | - | K15, P10 - P20 | - |

| Carbide designation US | - | C2, C7 - C6 | - |

| - | Coated 3) carbide | - | - |

- 1) For coated HSS end mill vc = 14 - 16 m/min.

- 2) Depending on radial depth of cut and cutter diameter.

- 3) Use a wear resistant Al2O3 coated carbide grade.

Grinding

A general grinding wheel recommendation is given below.

| Type of grinding | Soft annealed condition | Hardened condition |

| Face grinding straight wheel | A 46 HV | B 151 R50 B3 * A 46 GV |

| Face grinding segments | A 36 GV | A 46 GV |

| Cylindrical grinding | A 60 KV | B 151 R50 B3 * A 60 JV |

| Internal grinding | A 60 JV | B 151 R75 B3 * A 60 IV |

| Profile grinding | A 100 IV | B 126 R100 B6 * A 100 JV |

* If possible, use CBN discs for this application.

Electrical discharge machining - EDM

If EDM’ing (“spark-erosion”) is performed in the hardened and tempered condition, the tool should then be given an additional temper at about 20 °C (50 °F) below the previous tem-pering temperature.

Application

New types of engineering plastics with a high filler content place higher demands on the tool material in terms of wear and corrosion resistance. Uddeholm Elmax SuperClean has been specially developed for high-tech programs. These include products in the electronics industry such as connectors, plugs, switches, resistors, integrated circuits, etc. Uddeholm Elmax SuperClean can also be used in the food industry, for the production of custom knives, where a combination of corrosion resistance and wear resistance is necessary.

Advantages and disadvantages of Elmax stainless steel as a knife steel

A good knife should not only please the eye. It should also have high performance properties and be easy to use. Let's consider how Elmax stainless steel has proven itself.

Advantages

- Possibility of polishing the surface to a mirror shine.

- High anti-corrosion properties.

- Plasticity.

- Ability to withstand lateral loads.

- Maintaining the sharpness of the edge for a long time.

Disadvantages

There are no obvious disadvantages to Elmax stainless steel, but it would be unfair not to point out a few downsides.

- The high price of knives is due to the high cost of this grade of steel.

- Not 100% corrosion resistance - with prolonged use in a humid environment (especially with salt content) and lack of proper care, pitting corrosion is possible.

Conclusions:

- Elmax steel knives are expensive, but this is compensated by their high technical characteristics.

- For steel with high strength - very good impact toughness.

- Requires only minimal maintenance.

- Holds sharpening for a long time and is easy to correct.

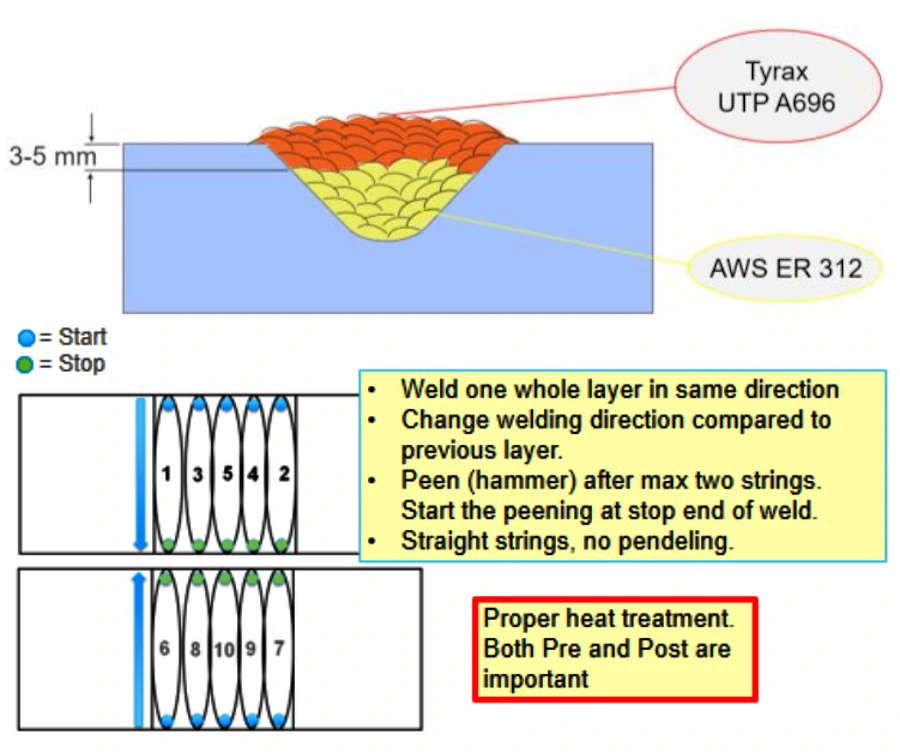

Welding recommendations

Uddeholm Elmax SuperClean is a high chromium-vanadium-molybdenum-alloyed steel with high wear resistance, high compressive strength, corrosion resistant and very good dimensional stability In Uddeholm Elmax SuperClean it has however been able to achieve this unique combination of properties by a powder-metallurgy-based production.

Welding of PM-steels is normally not recommended, due to the chance of failure, but good results when welding can be achieved if proper precautions are taken (joint preparation, choice of consumables and welding procedure). If the tool is to be polished, it is necessary to use a filler material that has the same chemical composition as the base material.

Dimensions of filler material

| Type | TIG | Laser |

| Dia. Ø mm | 1.6 | 0.2 - 0.6 |

| Tyrax TIG | X | - |

| UTP A 696 | UTP A 696 | - |

| Tyrax Laser Weld | - | X |

Recommended filling material

| Welding Method | Gas Tungsten Arc Welding GTAW (TIG) | Gas Metal Arc Welding GMAW (MIG/MAG) | Shielded Metal Arc Welding SMAW (MMA) | Laser | Comments |

| Filler material | Tyrax TIG UTP A696 | Not Recommended | Not Recommended | Tyrax Laser Weld | - |

| Type AWS ER 312 | - | - | - | Use soft filler material for buffering layer | |

| Hardness as welded | 60 - 64 HRC A696 58 - 62 HRC Caldie | - | - | 55 - 60 HRC | - |

Parameters

| Condition | Soft Annealed 215 HB | Hardened 58 - 60 HRC | Comment |

| Preheating Temperature | 350°C ± 25°C 660°F ± 50°F | 350°C ± 25°C 660°F ± 50°F | The temperature should be kept constant during the welding operation. Start with buffering layers if not all cracks are removed. Minor repairs up to 3 strings can be made without buffering layer. |

| Interpass temperature | Max 150°C, 270°F above preheating temperature | Max 150°C, 270°F above preheating temperature | The temperature of the tool in the vicinity of the weld. When passed, the tool will have a risk for distortion, soft zones or cracking in and around the weld (the HAZ). |

| Cooling rate | 20 - 40°, 35 - 70°F C/h The first 2 hours then freely in air <70°C, 160°F | - | |

| Post treatment | Soft anneal Harden Temper | Temper 25°C, 50°F below previous tempering temperature | Holding time when tempering, 2h. The temperature depends on the last used tempering temperature.* |

*Note. In many cases, a high temperature tempering for 2 hours at ~750°C (1380°F) acts as a substitute for a full soft anneal when welding soft annealed material.

Procedures

- Clean weld area.

- Preheat material to 350°C ± 25°C / 660°F ± 50°F and maintain temperature during welding.

- Do not let the temperature in the vicinity of the weld (the HAZ) increase more than 150°C / 270°F above the preheating temperature. There is a risk of lowering (softening) the hardness of the base material or/and cracking in the HAZ. Use temple sticks or other temperature-measuring devices.

- For finishing layers use consumables which give suitable hardness.

- Wait a few minutes between each layer of strings, both for soft and hard filler, in order to let the layer equalize and minimize stresses, if possible use pre- heating furnace. Peen to minimize stresses.

- If possible, change welding direction 180° between each layer.

- Cool slowly after welding, 20 - 40°C/h, 35 - 70 °F/h for the first two hours and then freely in air < 70°C / 160°F.

- Temper 25°C / 50°F below previous tempering temperature for two hours.

- Tools welded in the annealed condition must undergo a full soft annealing immediately after welding. Allow tool to cool to room temperature before soft annealing. If a complete soft annealing cannot be done, a high temperature tempering at 750°C / 1380°F could be used. Be aware of that the working properties of the material will be somewhat reduced, if the high temperature tempering is used instead of the soft annealing.

- Shield Metal Arc Welding SMAW (MMA) and MIG Welding is not recommended.

Heat treatment guidelines

Heat treating stainless steel is the process of heating and cooling a metal to change its physical properties. There are several types of heat treating stainless steel, each with its own purpose.

Heat treatment of stainless steel can be used to achieve various goals, such as:

- Increased strength and hardness.

- Improved plasticity and toughness.

- Reduced internal stress.

- Improved machinability.

- Changed magnetic properties.

Characteristics

- High hardness PM stainless steel.

- Excellent polishability.

- Can be readily surface treated.

- Good corrosion resistance and very good abrasive wear resistance.

This information is based on the current state of knowledge and is intended to provide general notes on the products and their use. It should therefore not be construed as a guarantee of specific properties of the products described or a guarantee of fitness for a particular purpose. It is your responsibility to ensure that you have the latest version of the steel manufacturer's document and that you forward it to your heat treatment service provider. Failure to do so may result in deterioration of the material properties.

| Vacuum | Salt Bath** / Fluidized Bed | Atmosphere Furnace Muffle Furnace / Packed | |

| ** Salt Bath heat treatment can be performed but is not recommended for details with blind holes or threaded holes that will not be rework after heat treatment. | |||

| Preheating Temperature | 1. Bring up to 1200°F, equalize 2. Heat up to 1550°F, equalize (optional) | 1. 1100 - 1200°F, equalize 2. 1500 - 1600°F, equalize | 1. Bring up to 1200°F, equalize 2. Heat up to 1550°F, equalize |

| Hardening Temperature (Austenitizing) | 1920 - 2010°F (Normally 1980°F) Holding time after the tool or part has fully heated through at the hardening temperature: minimum 30 minutes, maximum 1 hour. Alternatively hold 20 minutes for first 1” and then 15 minutes for each additional inch of wall thickness. | ||

| Quenching* | Alt. 1 Inert gas, positive pressure. Alt. 2 Back-filled pressurized gas to 1000°F, then equalize center and surface. Continue to 700°F and equalize. Then cool in circulating air. | Alt. 1 Quench in Salt 390-1020°F, equal then air cool. Alt. 2 Quench in oil 150°F until the part is black, then air cool. Alt. 3 Circulated air. | Alt. 1 Oil 150°F until the part is black, then air cool. Alt. 2 Circulated inert gas. Alt. 3 Circulated air. |

| *Cooling rate must be adequate to ensure good mechanical properties. However, also consider the risk of excessive distortion from very fast cooling. | |||

| • For maximum dimensional stability, a cryogenic treatment can be applied immediately after quench. An increase of 1-2 HRC can then be expected. However, avoid intricate shapes due to the risk of cracking. | |||

| Tempering (minimum two times) Temper immediately after quenching when the tool or part reaches 150°F | Hardening Temperature: Tempering Temperature Tempering Times: 1 hour per inch of wall thickness, or hold at temperature a minimum of 2 hours. | ||

| Stress Temper performed on hardened tools after EDM or welding | Check hardness to confirm tool status. Temperature: Shall be 50°F below the lowest tempering temperature. Time: Soak 30 minutes per inch of maximum section with a minimum of 2 hours once tool comes to temperature. Cool in still air. Caution: Stress tempering in an unprotected atmosphere will oxidize the tool. For hot work applications, this can prove beneficial to protect the tooling surface during operation. However, in other applications where surface finish condition is a concern, consult your heat treater on options for protective atmospheres or finish the surface after stress tempering. | ||

| Dimensional Stability | Average size change as a result of hardening and tempering may not exceed 0.003 inch/inch/maximum dimension if the tool has been stress relieved before finish machining. If stress relieving is not performed as recommended, dimensional stability may be inconsistent and cannot be guaranteed. | ||

The choice of the type of heat treatment depends on both the grade of stainless steel and the desired properties of the metal that need to be obtained after such treatment.