Welding recommendations

Uddeholm Elmax SuperClean is a high chromium-vanadium-molybdenum-alloyed steel with high wear resistance, high compressive strength, corrosion resistant and very good dimensional stability In Uddeholm Elmax SuperClean it has however been able to achieve this unique combination of properties by a powder-metallurgy-based production.

Welding of PM-steels is normally not recommended, due to the chance of failure, but good results when welding can be achieved if proper precautions are taken (joint preparation, choice of consumables and welding procedure). If the tool is to be polished, it is necessary to use a filler material that has the same chemical composition as the base material.

Dimensions of filler material

| Type | TIG | Laser |

| Dia. Ø mm | 1.6 | 0.2 - 0.6 |

| Tyrax TIG | X | - |

| UTP A 696 | UTP A 696 | - |

| Tyrax Laser Weld | - | X |

Recommended filling material

| Welding Method | Gas Tungsten Arc Welding GTAW (TIG) | Gas Metal Arc Welding GMAW (MIG/MAG) | Shielded Metal Arc Welding SMAW (MMA) | Laser | Comments |

| Filler material | Tyrax TIG UTP A696 | Not Recommended | Not Recommended | Tyrax Laser Weld | - |

| Type AWS ER 312 | - | - | - | Use soft filler material for buffering layer | |

| Hardness as welded | 60 - 64 HRC A696 58 - 62 HRC Caldie | - | - | 55 - 60 HRC | - |

Parameters

| Condition | Soft Annealed 215 HB | Hardened 58 - 60 HRC | Comment |

| Preheating Temperature | 350°C ± 25°C 660°F ± 50°F | 350°C ± 25°C 660°F ± 50°F | The temperature should be kept constant during the welding operation. Start with buffering layers if not all cracks are removed. Minor repairs up to 3 strings can be made without buffering layer. |

| Interpass temperature | Max 150°C, 270°F above preheating temperature | Max 150°C, 270°F above preheating temperature | The temperature of the tool in the vicinity of the weld. When passed, the tool will have a risk for distortion, soft zones or cracking in and around the weld (the HAZ). |

| Cooling rate | 20 - 40°, 35 - 70°F C/h The first 2 hours then freely in air <70°C, 160°F | - | |

| Post treatment | Soft anneal Harden Temper | Temper 25°C, 50°F below previous tempering temperature | Holding time when tempering, 2h. The temperature depends on the last used tempering temperature.* |

*Note. In many cases, a high temperature tempering for 2 hours at ~750°C (1380°F) acts as a substitute for a full soft anneal when welding soft annealed material.

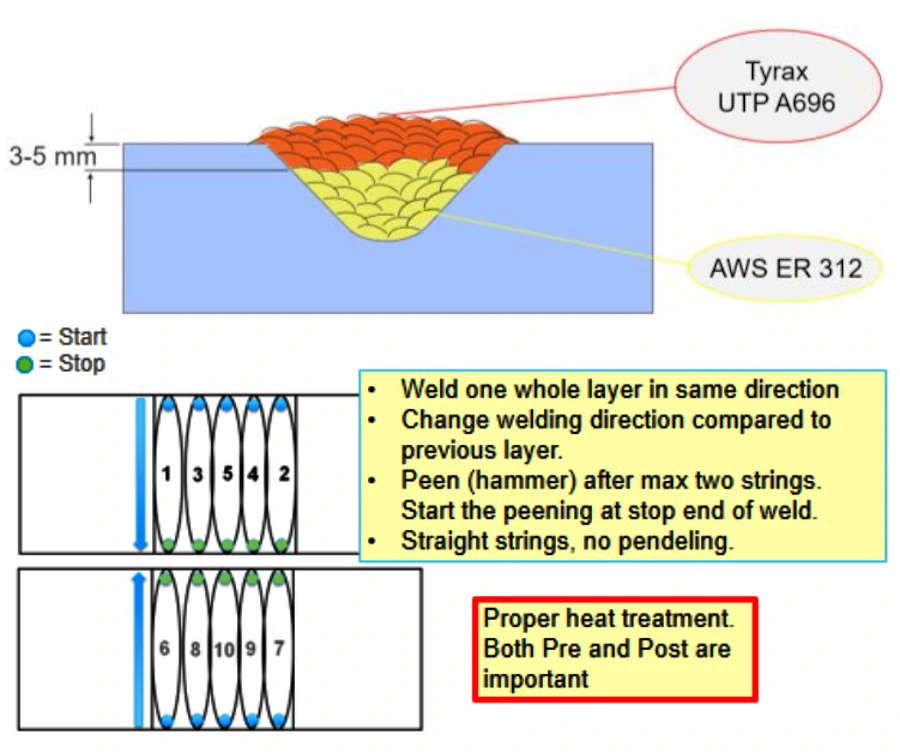

Procedures

- Clean weld area.

- Preheat material to 350°C ± 25°C / 660°F ± 50°F and maintain temperature during welding.

- Do not let the temperature in the vicinity of the weld (the HAZ) increase more than 150°C / 270°F above the preheating temperature. There is a risk of lowering (softening) the hardness of the base material or/and cracking in the HAZ. Use temple sticks or other temperature-measuring devices.

- For finishing layers use consumables which give suitable hardness.

- Wait a few minutes between each layer of strings, both for soft and hard filler, in order to let the layer equalize and minimize stresses, if possible use pre- heating furnace. Peen to minimize stresses.

- If possible, change welding direction 180° between each layer.

- Cool slowly after welding, 20 - 40°C/h, 35 - 70 °F/h for the first two hours and then freely in air < 70°C / 160°F.

- Temper 25°C / 50°F below previous tempering temperature for two hours.

- Tools welded in the annealed condition must undergo a full soft annealing immediately after welding. Allow tool to cool to room temperature before soft annealing. If a complete soft annealing cannot be done, a high temperature tempering at 750°C / 1380°F could be used. Be aware of that the working properties of the material will be somewhat reduced, if the high temperature tempering is used instead of the soft annealing.

- Shield Metal Arc Welding SMAW (MMA) and MIG Welding is not recommended.