Stainless Steel Grades Directory

AISI 203 | S20300 is one of the 200 series austenitic stainless steels containing a high percentage of chromium and nickel. The nickel and chromium content makes the alloy resistant to many chemicals, including chlorine, sulfuric and nitric acids. As a result, it is not affected by extreme temperatures and is often used in cryogenic systems.

- Details

- Written by: ukirs

- Hits: 241

AISI 422 | AISI 616 | EN 1.4935 | DIN X20CrMoWV12-1 is a high-alloy stainless steel with a martensitic crystal structure and good corrosion resistance. It is mainly used for parts exposed to high temperatures of up to 649 °C. With the right heat treatment, parts of this steel can also have excellent mechanical properties depending on the cross-section, shape and application.

- Details

- Written by: ukirs

- Hits: 135

Stainless steel grade AISI 429 | EN 1.4001 | DIN X7Cr14 is a ferritic steel. It is also known as chromium steel UNS S42900. This steel has good corrosion resistance and its weldability is better than that of AISI 430. In fact, it is a modified version of AISI 430 (AISI 429 has slightly lower chromium content than AISI 430).

- Details

- Written by: ukirs

- Hits: 164

AISI 430F | EN 1.4105 | DIN X6CrMoS17 and EN 1.4104 | DIN X14CrMoS17 are close in chemical composition and some properties to stainless steel grade AISI 430 (EN 1.4016). But there is a slight difference. The differences are in the addition of sulfur and molybdenum to their composition. Sulfur makes the chips easily breakable during processing. Sulfur is as dangerous as oil, so the processing process can be done very quickly using these grades of stainless steel. Since sulfur reduces the level of corrosion resistance, a small addition of molybdenum was added to this grade.

- Details

- Written by: ukirs

- Hits: 159

AISI 436 | EN 1.4526 | DIN X6CrMoNb17-1 is a ferritic stainless steel alloyed with molybdenum. It is an improvement of the AISI 434 grade with a small stabilizing additive of niobium. Suitable for use in many aggressive environments. Can be welded without fear of intercrystalline corrosion.

- Details

- Written by: ukirs

- Hits: 123

AISI 420F | EN 1.4029 | DIN X29CrS13 - is a martensitic alloy. The grade is identical to stainless steel AISI 420, but with the addition of sulfur to significantly improve machinability. This alloy has excellent corrosion properties when quenched and provides good ductility in the annealed condition.

- Details

- Written by: ukirs

- Hits: 197

AISI 414 | EN 1.4008 | DIN GX7CrNiMo12-1 is a martensitic stainless steel designed for primary forming of wrought products. It has moderately high tensile strength among wrought martensitic stainless steels. This alloy is actually an improved version of AISI 410. The addition of nickel to its composition resulted in a steel that is stronger than AISI 403 and AISI 410 at similar strength levels.

- Details

- Written by: ukirs

- Hits: 237

Stainless Steel Round Pipe

Stainless Steel Round Pipe  Stainless Steel Square Pipe

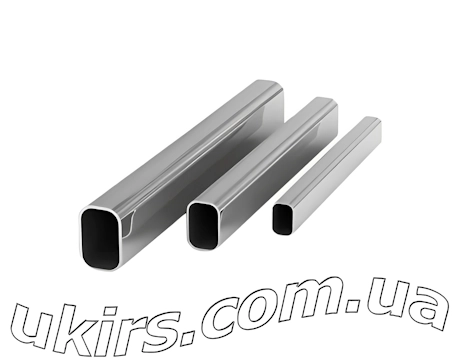

Stainless Steel Square Pipe  Stainless Steel Rectangular Pipe

Stainless Steel Rectangular Pipe  Stainless Steel Oval Pipe

Stainless Steel Oval Pipe  Stainless Steel Elbow

Stainless Steel Elbow  Stainless Steel Decorative Cover

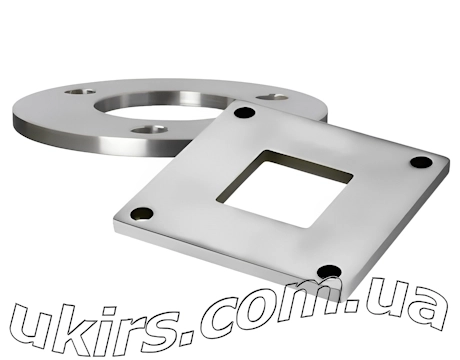

Stainless Steel Decorative Cover  Stainless Steel Flange

Stainless Steel Flange  Stainless Steel Plug

Stainless Steel Plug  Stainless Steel Handrail Holder

Stainless Steel Handrail Holder